21st

April

2010

Match-drilled both of the top skins to the structure, except for the longerons — since the underlying holes have already been drilled & dimpled, I’ll just run a reamer through all those holes in the top skins after they come off. Also match-drilled the 710 bulkhead to the aft deck.

Browse the manual, what’s next? Steps…I’ve read this is tricky and I can see how it could be. The first step was to trim the end of the step tube, which was too long, and hit the baggage rib before the flange seated on the skin. The flange was about 1/4″ away from sitting flat, so I trimmed 1/4″ off the end, and somehow ended up 1/8″ short. Sigh. I’ve heard that there is some variation in these things–some too short, some too long, so I’m not going to worry about it, and may fabricate a spacer to bring the plastic block out the extra 1/8″.

Patience is certainly required, as there is much repetition of the bend-fit-remove cycle, trying to get the step flange to mate nicely with the side skins. After several tries, including some filing and a trip to the grinding wheel, I finally got a decent fit. Once fit, I pulled the step off and laid out two holes in diagonal corners, drilled, then back-drilled to the fuselage and clecoed in place. Marked the centerline of the rib that one row of rivets picks up, and removed again to lay out the rest of the hole pattern. I used only 4 rivets in the rib row, instead of 5, as at least one of the 5 would have been drilled through half of an existing skin rivet. With four, I was able to split the distance between the five skin rivets under the flange and have good edges distance on everything.

Several more fit-remove cycles were involved in fitting the plastic block that fixes the inner end of the tube to the rib, since my angle drill is too fat to fit in there nicely with the step tube there. I marked the hole with a #11 bit, then removed and drilled, before putting it back in place. For now, I bolted it to the rib, but did not drill the hole through the step tube, in anticipation of a spacer being fitted behind the block later.

Hours: 3.2 | Posted in Upper Fuse & Skins |

19th

April

2010

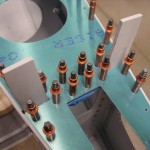

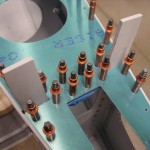

Vertical Power announced their new VP-X system a few weeks back, which–at least to me–is sort of a hybrid of their existing systems. It has a boatload of power circuits, 10 assignable switch inputs where you can use whatever type of switch you desires, built in wig-wag control, trim speed adjust, flap positioning system, etc. There is no dedicated display unit; instead, you can use your own switches, and it connects to your EFIS for display needs and to allow switching of individual circuits (beyond what you have access to with the switch inputs). I was sold on the VP stuff when it came out a couple years back, but their systems didn’t allow for the switchology I had in mind, so I had resolved to use fuses & such. This new system is exactly what I needed, so with the fuselage coming together, I called up Marc and Vertical Power and ordered the wiring harness kit, and an empty control unit (CU) shell. I was also inspired to start fooling around with panel designs in Turbocad, and looking at different switch options.

Anyway, my order with the CU shell and wiring kit arrived today, after a UPS delay:

…of course, there’s still another several hundred dollars worth of wire, connectors, and so on to be bought for antennas, sensors and the like…I have a good part of my electrical design scratched out, and an order list for a bunch of wire from Steinair; hoping to get some wiring in before the tailcone closes and avoid as much belly-crawling as possible.

Posted in Electrical |

18th

April

2010

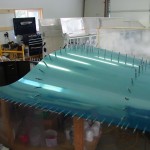

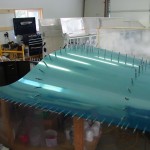

Pulled out the J-stiffeners that were made for the upper fuselage back when the rest of the stiffeners were cut; set them in place and taped their forward edges to the baggage bulkhead. These run three bulkheads back, and need to be drilled in assembly using the holes in the top skins. So, the aft top skin was clecoed in place first, to the bulkheads and longerons (after adjusting the angles of the bulkhead flanges to account for the taper of the fuselage). Once that skin was in place, the gussets connecting the 707 bulkhead to the longerons were clamped for later drilling (once the aft skins are removed, allowing access).

Next, the structure under the forward top skin is set in place: a gusset (which the manual calls F-688 and indicates needs to be cut & drilled, but in reality is F-788, complete and prepunched), and a rib. The forward end of the rib is clecoed to the baggage bulkhead, and the aft end affixed to the 707 by way of a cleat which is fabricated from a short length of angle. Before the cleat can be drilled in assembly, the skin must be set in place, so that happened next: skin in place and the J-stiffeners drilled from it. After the stiffeners are drilled, the skin is opened up along one side to give access for drilling the cleat to the bulkhead and the rib. After drilling and clecoing in place, the skin flap is clecoed back down. With both skins in place, the aft bulkhead that closes out the top of the fuselage is set in place, and the bottom-most holes drilled using the skin as a guide.

Once these skins are drilled, they will be pulled off for deburring, etc. I plan to get the static system and wiring into the aft fuselage before they are reattached permanently. 2 1/2 more pages in the manual until the first fitting of the wings–seems close, but it’s probably deceivingly far off.

Hours: 2.5 | Posted in Upper Fuse & Skins |

17th

April

2010

Completed drilling the aft deck spaces, fit and drilled the forward gussets at the firewall/upper longeron intersection. Drilled the harness anchors to the longerons, riveted the bellcrank support to the baggage bulkhead, and clecoed the small gussets that affix some of the tailcone bulkheads to the longerons. I’ll wait to clamp these in place until the aft skins are clecoed on.

In spare time, doing mental and paper fiddling with the electrical system and antennas. I believe it will be easier to “design in” those things, rather than build the fuselage and add them afterwards.

Hours: 2.1 | Posted in Upper Fuse & Skins |

16th

April

2010

Now that the fuselage is upright, there is a myriad of small parts to be attached. Today, I finished drilling the aft deck to the longerons. I also fit the gussets behind the seats, which needed holes cut in them for the canopy latches to drop through. This also involved clecoing on the canopy decks, though I am sure they’ll end up coming off and on a couple more times. Finally, I fabricated the two spacers that fit under the aft deck, clamped them in place, and began drilling them in place.

Hours: 2.3 | Posted in Upper Fuse & Skins |

12th

April

2010

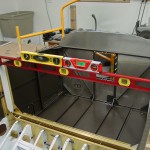

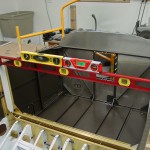

Picked up a digital level during the weekend out of town, so today I set out to level the fuselage and fit the aft deck. First task is leveling the fuselage, since it sits rather nose-up when placed on two equal-height sawhorses. After a couple of tries with various height objects, I got the front of the fuse set on a fixture of scaffolding and 2×4′s, and the tail supported with a sawhorse. One shim between a couple 2×4′s levelled the forward fuselage in the roll axis, and sliding the sawhorse fore/aft allowed it to be level in pitch. Twist is removed by adjusting the aft deck and clamping in place, which was surprisingly easy. (I was also interested to see that the 0.1-degree precision of a digital level is rather obvious on a bubble level, so perhaps the need for a digital level at this step is overstated, though it will surely come in handy when measuring control surface throws.)

With the aft deck clamped securely, I took two more series of measurements before picking up the drill. I also left the level in place on the aft deck so I could check it between holes, in order to avoid any twist creeping in. I drilled every other hole before it was time to head in for dinner. The fuselage structure is now rigidly fixed in place.

My package of LED lighting strips also arrived today, direct from Hong Kong (SMD 3528 style from ledlightsworld.com, with the “IP65 waterproof-surface” rating). I’ve been using these for a project at work, and think they should serve nicely for interior lighting…I ordered blue for the panel, and warm white for general cabin/baggage lighting. I already have some PWM dimmers that I picked up some time back from another builder. I’ll have to play around and determine the best place to put them for cabin lighting, and the switchology.

Hours: 2.2 | Posted in Upper Fuse & Skins |

3rd

April

2010

This was the big day. Allison was back in the shop, and we started the fun by re-setting the outboard floor stiffeners from yesterday, then completed the inboard stiffeners. Riveted the aft row of rivets at the firewall (the forward row doesn’t get installed until cowling work). There’s a few tricky ones in there: the outboard few where the firewall weldment is very nearby, and the couple which are almost under the inboard angle brackets where the engine mount bolts on. With a few different bucking bars (including a big crowbar), we made it work.

While Allison took a break, I squeezed the longeron rivets that do not attach any top skins, leaving a patten of holes open on the left side for the clips that will retain the static air tubing. Next, I climbed under the fuselage and riveted the aft baggage-rib-to-bulkhead rivets.

After that was done, it was on to the tailcone join, which went quite quickly, just a couple rows of rivets, and up the side of the conical bend area.

With all the riveting done, there was nothing left to do but take the plane through its first (and only) aileron roll… (can you do an aileron roll with no ailerons?) The canoe is flipped! Total build time to this point: 745.1 hours. Now the real fun begins!

Hours: 2.4 | Posted in Center Fuselage |

2nd

April

2010

Two steps forward, .8 steps back… Allison came out tonight and helped with riveting — we did both fore & aft rows at the center section bulkhead, and the outboard floor stiffeners. About 5 minutes after we finished the floor stiffeners, I came to the realization (through a convoluted thought process) that the left and right outboard floor stiffeners had been transposed when clecoed in. (I must have mismarked them after etching and priming.) Essentially, this meant that the vertical leg of the angle was toward the outside of the fuselage, instead of the centerline. Looking ahead in the plans, I could see no problems this would cause, except for two things: first, the panels which hide the fuel & brake line runs would need to be altered, to move the notch for the vertical leg of the stiffener angles outboard about 1″; and second, any carpet underlayment foam would have to be cut to non-standard dimensions…not a big deal, but something to remember when ordering interior stuff, since the foam often comes with the carpets.

After some internal debate, I decided that I would just drill the things out, swap them, and be done with it. 50 rivets to drill out, all of which went fine without any problems. We’ll re-set these in tomorrow’s batch.

Hours: 2.1 | Posted in Forward Fuselage |

26th

March

2010

With Allison helping tonight, wrapped up the remaining right skin rivets, and did all the left skin rivets. Bottom side left to go.

Hours: 1.9 | Posted in Forward Fuselage |

22nd

March

2010

Riveted most of the right side skin with Allison.

Hours: 2.1 | Posted in Forward Fuselage |