21st

March

2010

Riveted the baggage wall ribs to the side skins, and the double row of rivets at the tailcone join, up as far as I could reach. All the remaining riveting will require a second pair of hands, as my arm-length is maxed out. After the riveting I could do was done, I putzed around looking at things on the fuselage and in the plans, shaping the picture in my head of how the next set of parts goes together.

Hours: 2.0 | Posted in Center Fuselage |

20th

March

2010

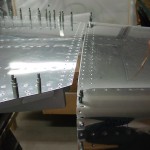

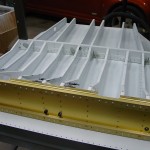

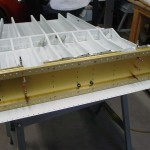

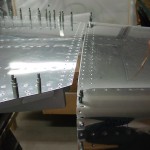

Progress is being made on the fuselage riveting…I first set the two remaining rivets on the inboard floor stiffeners, then clecoed in the armrests and baggage side wall ribs. The lower longerons were bolted to the firewall weldments; torqued, sealed, and the bottom floor skin clecoed in place, followed by the outboard floor stiffeners.

With all the components now clecoed together, there’s nothing left to do but rivet! Working from a stepstool as a seat, I was able to reach about 2/3rds of the way up the side walls, and completed everything I could reach back to the 705 bulkhead, along with all the longerons and bulkheads aft of the 706. I should be able to get most of the baggage walls and 705/706 bulkhead-skin rivets in a similar manner. I was also able to reach about half the rivets joining the side skin to the outboard seat ribs, by reaching through the aileron pushrod holes.

Hours: 5.1 | Posted in Center Fuselage, Forward Fuselage |

19th

March

2010

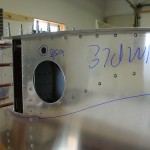

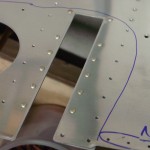

Finished up a couple odds ‘n’ ends, and started the fuselage riveting tonight. I had read that the rivet immediately above the rear spar bars can interfere with the rear spar stub on the wing, so I dimpled that location for a flush rivet. Also pre-riveted the center section doublers to the side skins as called for (though the plans call out 5 and 6 rivets, I believe they mean 6 and 7; Smitty came to the same conclusion.) Riveted the angled side ribs to the skin on all rivets that aren’t shared with the side skin; this required temporarily removing the bolt from the rear spar to gain access to the rivet tail.

With those preparatory steps out of the way, it was time to marry the tailcone and center fuselage for the final time. Once the double row of holes on the bottom was clecoed, I added the longerons and clecoed up to the 904 bulkhead, then added the side skins and clecoed those in place. Firewall is added next–the angles clips and side stiffeners must be riveted to the firewall at this point if not already done, as access is limited once the side skins go on.

After the firewall was in place, I added all the structural pieces between the 904 and the firewall. Squeezed the accessible rivets on the inboard floor stiffeners in preparation for adding the forward bottom skin. Shortly after that, I squeezed my left pinkie finger, so it was time to call it a night. The aftmost rivets on the floor stiffeners will need to be set with the gun, as they’re tucked too far under a flange to get at with the squeezer.

Hours: 3.4 | Posted in Center Fuselage, Forward Fuselage |

15th

March

2010

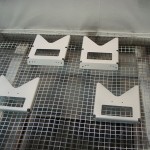

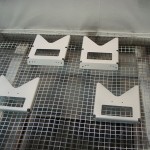

With the install of the crotch strap brackets today, the fuselage is nearly ready for riveting. Before the brackets could be fit, I riveted the two seat ribs to the bottom skin and vacuumed all the metal chips out of the center section. After deburring them to prevent scratching up the ribs, the brackets were then fit in place, with spacers clamped between the fore & aft brackets to provide proper spacing. The angle drill extension allowed me to get in there and drill — this cheapo extension feels like it may be dying inside, so hopefully it’ll hang on to life for a bit yet. I would be tempted to replace it with a real angle drill with a small head, as the wider body on this one sometimes results in slightly angled drilling.

With the brackets removed, and holes deburred, I vacuumed the center section once more, etched and primed the brackets. Discovered that the Stewart Systems primer is too thick for the Preval sprayers, so I’ll have to try it thinned down a bit…for now, I just loaded up the gun and shot with that. After the primer had set (sped up by setting them under the infrared heater, which has been a godsend for cold-weather priming), I clecoed them in place and pulled the 40 blind rivets that hold them in.

Clecoed the angled side ribs to the bottom skin in preparation for riveting, along with the forward tab that connects the rib to the 705 bulkhead. Need to remember to revisit one rivet location near the rear spar on the side skins, that others report really should be a flush rivet to prevent interference with the rear spars later on. After the angled ribs are riveted on, the tailcone can be attached again and riveting can commence.

Hours: 4.8 | Posted in Center Fuselage |

14th

March

2010

Heard back from Van’s on Tuesday about the seat pan ribs — Joe said it was alright to have the elongated holes, just use a nut and washer. I’ll be more careful, next time, really! (Browsing his build log for an unrelated topic, I saw that Chad Jensen actually made the same mistake; he fixed it by a different method–widening the crotch strap brackets–which would have been easier, had I any suitable scrap sheet…)

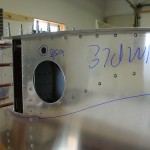

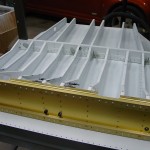

So tonight, after buying some paint supplies at Menard’s, I shot interior color on the side skins and longerons. The paint goes on pretty nice with the gun (thinned 8oz/quart with xylol); I think it’s even easier to get an even finish than with the rattle cans, though of course the rattle cans are easier to deal with, esp. for small parts. Also shot a scrap piece with some tan textured paint we picked up to try for the rudder pedals…I’ll give the test piece to my interior designer (hi, Allison…) for evaluation.

After the joy of painting ended, I squeezed nutplates onto the various uprights and stiffeners that receive them, and did some other riveting: the gear attach webs, spacers, and tank attach angles; that whole assembly to the side bulkhead uprights, the little angle “clips” to the side stiffeners, and the lower longeron gussets to the firewall side angles. Touched up primer in a couple spots that needed it on some of the pieces.

Lastly, I addressed the center section: clecoed the two now-correctly-placed ribs in place and drilled the 3/16″ holes, then removed for deburring, spot primed where needed, and re-clecoed in place. Once they were fit, I riveted their fore and aft ends to the bulkheads. One hole in the lower rear spar got a little messed up in the drilling out earlier, and rivets kept clinching over; that one ended up with a short AN3 bolt (always a defeating moment, but probably the best thing to do…and no one will ever see it down there anyway).

Tomorrow, I hope to finish re-riveting those two ribs (easy), and start putting the fuselage back together for final riveting.

Hours: 3.2 | Posted in Center Fuselage |

8th

March

2010

Sprayed interior color on most of the batch of parts — the side skins and longerons remain. I will pick up a quart can of the paint to do the side skins, as they would be rather tedious to do with a rattle can…

Hours: 2.5 | Posted in Forward Fuselage |

7th

March

2010

Etched the skins and longerons, then shot primer on all the parts. Interior paint later this week, and with any luck, final assembly can begin on the weekend.

Hours: 6.0 | Posted in Forward Fuselage |

6th

March

2010

Etched all the fuselage components that are done to date, except for the side and forward bottom skins, and the main longerons. Those are big enough that they really need to be done outside (the etch solution eats the concrete floor, and they’re too big to fit in the big plastic tray I use for etching parts); we’ll see if the weather is good enough tomorrow to get it done. Should be able to get the priming done this week.

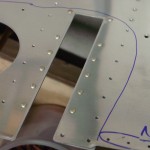

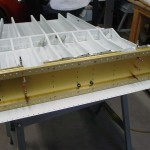

After tiring of etching, I thought I’d look at the install of the crotch strap brackets. This is where I discovered a dormant screw-up that I was previously unaware of. Turns out that when I initially fit the seat ribs to the center section, I got the inboard pair of F-916 ribs reversed. That is, the inboard F-916-L goes on the right side, and vice versa. Unlike some other parts of the plane, it’s completely possible to reverse these with no ill effects–the seat pans, bottom skin, and everything else all fit perfectly, so nothing screamed “wrong!” Until I held the crotch strap brackets in place, when it became very evident what had happened. The space between the ribs that are spanned by the bracket is about 3/4 of an inch too wide. Since the center section isn’t yet attached to the tailcone, access to drill out and re-rivet these ribs isn’t a problem, so I drilled both out and put them in the correct orientation. Easy enough, except for one thing: the 3/16″ holes that were match-drilled from the main spar, where AN3 bolts are inserted, are not in alignment with the line of rivets that runs down the forward flange of the ribs, but rather offset by a small amount. This means that when the already-drilled ribs were flipped into the correct orientation, those 3/16″ holes are out of alignment by about 1/2-diameter, which would result in ovalled holes if drilled. I’ve sent an email off to Van’s asking their advice–my guess is that they’ll say it’s fine, put in the bolt and move on, since that rib is also held in by a bunch of rivets. But better to ask…if the ribs need replacing, it should be easy to do that, too…for $17.73 apiece, plus shipping. Sigh. I feel like I’ve made several stupid mistakes lately.

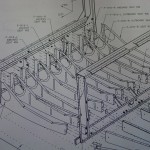

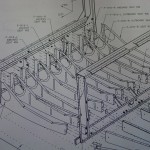

(The ribs in question are the third in from each side on the drawing — the inboard “F-916-L/R outboard seat rib”. Marked by the clecos on the second photo.)

Hours: 4.9 | Posted in Center Fuselage, Forward Fuselage |

1st

March

2010

Went to the shop after fixing the garage door opener (new drive gear & bushings have it running smoothly again) with the intent of figuring out some antenna doublers, thinking that it would be a good idea to install them while access to the fuselage is easy for dimpling, deburring, and riveting. Stood around staring at it for awhile, pondering, and made no progress on that — wondering if now is really the time, or not. My proposed list of antennas:

- VHF Com 1 and 2 (Comant CI-122 bent whips): install under removable portion of seat pans, behind wing spar, left and right outermost bays of fuselage

- VOR/LOC/GS (Comant CI-157P or CI-158C “cat whiskers”): bottom of tailcone, just behind fwd edge of aft bottom tail skin

- Transponder (DeltaPop): near centerline of tailcone, somewhere aft of F-706 bulkhead [must be +3' from transponder itself]

- ADS-B (DeltaPop): right side fwd fuselage, near front fuel vent [must be +4' from transponder antenna]

- GPS (whatever 430W specifies): top side of fuselage aft of F-706

- GPS2, GPS3 (?): under cowling or aft canopy window?

- ELT (whatever is specified): undecided, perhaps top of fuse or along roll bar

- APRS (VHF com or Loran antenna?): undecided, perhaps opposite of ADS-B, or in a wingtip

Lots of stuff to think about. The two of these where access would be most restricted in the future would be the transponder and the VOR, as they are aft of the cabin area, and perhaps the VHF comms. I’ve looked all over the web and seen many different ways of mounting antennas: some use no doubler, some use a “floating” doubler secured only by the mounting bolts of the antenna itself, some rivet a flat doubler to the skin, some use a flanged doubler riveted to the skin, and some tie a doubler into nearby structure (either with or without riveting to the skin as well). The latter ones seem sturdiest, but are they overkill? I’m probably making this far more complex than it needs to be, but it seemed that this would be the ideal time to put these in, if they were to be riveted to skin and/or structure.

With all that indecision rolling about, I found something easy to do, even though it’s not needed for awhile: I laid out and cut the lightening holes in the seat back supports, and marked their flanges for trimming. And, I drilled a 1/4″ hole in the left side of the 705 bulkhead, just under the longeron, for routing of the static line. Whee.

Hours: 0.5 | Posted in Cabin & Interior |

27th

February

2010

Finished the final deburring on the side skins, and dimpled the three skins with help from Allison. Fuselage parts are now ready for priming, which will probably be next Sunday when I next have a large block of time to spend.

Hours: 3.1 | Posted in Forward Fuselage |