A month and a half on, flight testing continues. As of today, the Hobbs reads 23.00; subtracting the various ground-run time done in pursuit of certification and engine troubles, I have 20.8 flight hours on the plane so far…half done with Phase I operations.

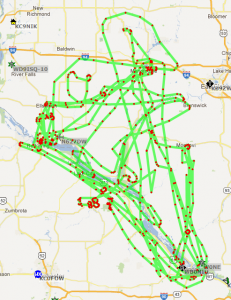

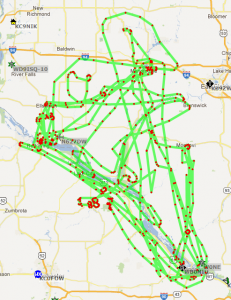

4 days of APRS squiggles, various speeds and altitudes; it’s clear I’m using all of the small test triangle.

Engine break in appears to have gone well, using oil consumption as an indicator; she used or blew out 1/2 quart in the first few hours, then slowly dropped to 7 quarts, where it stayed until I changed the oil this weekend. On the advice of folks who said that filling it to capacity (8qts) will just dump a quart out the breather, I refilled to 6 qts indicated after the oil change. 7.4 hours of flight time since the oil change, and the level hasn’t budged…still at 6 qts. Excellent.

Other than the engine stumble/miss, the problems seem to have been sorted out…

- The cabin CO level seems to have been resolved by the reseating of the #4 exhaust stack, where there was evidence of a small exhaust leak.

- I did the first oil change at 10 engine hours this weekend, without making too much of a mess. I also took the opportunity while the sump was empty to remove the quick-drain valve, then clean and reinstall it with better thread sealant — hopefully this will stop a very small weeping leak at the threads.

- The heavy left wing was out of balance by ~9gal of fuel. I took another critical look at rigging, and found the left flap was being pulled up tighter than the right; I lowered the left by 1 turn on the rod end bearing, and that brought the imbalance to ~5gal. Before that, I’d experimented with a small trim tab on the right aileron to see what effect it had…nil. Today, I taped a larger trim tab (6″ x 3/16″) to the right aileron, and she flew nearly hands-off. I’ll get some ballast weight to load in the passenger seat, to take the solo-weight imbalance out of play, and see where we are then — if the trim tab is even needed with an even weight distribution. Once we’re close enough that the roll trim can handle it (Van’s suggests <=3gal imbalance), I’ll pull the seat pans and hook up the roll trim mechanism.

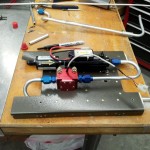

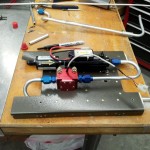

I spent Monday — which I deemed too gusty to fly (at one point something like 19G28 @ 60° from runway heading) — reinstalling the fuel flow transducer. As part of the engine troubleshooting, the transducer was removed from the FWF area. Due to mounting considerations, I decided to reinstall it in the center tunnel, under the “doghouse” with the fuel pump. The law of unintended consequences soon arrived, and I ended up remaking every piece of fuel tubing between the selector valve and the firewall, in order to make everything fit and work. In the end, though, I believe the install will be more maintainable, since the new configuration makes it easier to get the pump/filter assembly out of the plane. (I did open and clean the filter while I had it all apart; there was a minor amount of schmutz in there that I attribute to the several thousand paper towels that were used to clean the fuel tanks during the Proseal process…) Also required with the pluming changes was reflushing the fuel system and a new set of flow tests…I’d estimated the job at 4 hours, but it ended up being 10+ when all said & done.

The nagging problem is the engine stumble/miss. In addition to removing the 40″ of hose + FF transducer, and replacing it with 29 inches of hose, I also added a heat shield sleeve to the entire fuel servo->spider fuel line. I’ve not really noticed any difference in operation…it still stumbles/misses (engine folks have said that they use the word stumble for a different symptom) on low RPM operations (final approach & taxi-in, notably) when the engine is warm. Now that I have a larger body of data behind me from test flights, I’ll call Airflow Performance again to see if they have any additional suggestions–if they think it’s still a boiling fuel issue–and talk to Aerosport Power after that. I can’t see anything else to do with the fuel system WRT heat loading, other than buy & install the fuel pump cooling shroud that Van’s offers–it couldn’t do any harm, and the pump is definitely hot, but I’ve heard it is a major PITA to install. Otherwise, we have a forecast cold weekend coming up, which could provide some insight. (Though, in my opinion, OAT’s in the 60′s and 70′s shouldn’t be causing a problem…)

Flight testing is moving on…in addition to burning up time doing some sightseeing around the test area (leaves are changing fast, and fields being harvested), plenty of actual testing has been done, too:

- Climb speed tests from 3000′ to 8500′.

- Glide speed tests on the way back down.

- Climb to and short cruise at 12,500′.

- Exploration of power-off stall characteristics: straight ahead, and in increasing banks left & right to 30°. With flaps up, half, and full. She’s quite well behaved in all configurations; some exhibit a slight left-wing down tendency, but nothing excessive, extreme, or not easily remedied. After flying the stall series, I can make it consistently break straight. The prop-stopped stall from my first flight has never repeated itself, even through the 30+ stall series I did over the weekend.

- Partial power-on stalls.

- Exploration of slow flight and MCA regimes with flaps up and down.

- Tweaks to radio mic gain to improve transmission audio quality.

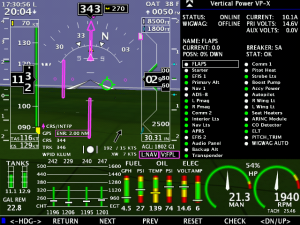

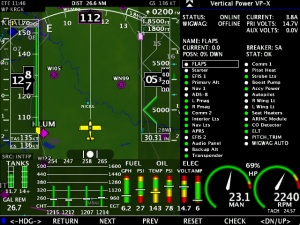

Since the engine break in is pretty well done, time to start experimentation with LOP operations; initial testing leaning from 75% power, 6.8gph (~50LOP) gives about 145ktas, and 28smpg (better than all of our cars except Allison’s little coupe). It gets pretty rough beyond that, but I still have the Pmags set in “stock” config, with the low advance curve…rumor says that selecting the higher curve improves LOP operations; we shall see. CHT’s and oil temps have been great all along; CHT’s on the front cyls are a bit higher than the rears, as expected, but no one is too warm, even on extended climbs.

For fun, today’s test was economy…partial power LOP, at C-150 speeds. ~90ktas, 2.5gph = 42smpg with over 9 hours endurance. Even better economy might be out there, with different settings — I just set this up to see what it would do at C-150 speed. I will also be curious to see what transpires when I get the intersection fairings on, and then have the prop repitched (possibly over the winter, or in the spring months when light & work schedule will conspire to prevent much flying time) to better match the engine & airframe.

I’ve done landings at all of the Phase I area airports now…Red Wing, Boyceville (short & narrow), Menomonie, and Winona. Winona is a rough airport–the surfaces are deteriorated, and has the highest fuel price (Menomonie is lowest at the moment, followed by Boyceville); I’ve fueled everywhere except Winona. At Menomonie yesterday, I stopped at the pump, and a fellow building an -8 came over to chat, along with the FBO owner or manager; nice folks, nice airport. I did 3 landings there tonight before returning to base as the sun set. I’ve selfishly been timing my return & landing so that I get to see the sunset, and the lights in the towns below coming on, along with the airport beacon & runway lights…it’s a nice sight, though none of my sunset photos so far have done it any justice. I did get this nifty picture of some farm fields north of Winona in the low sunlight tonight, though…

I have photographed nearly every decent town in the Phase 1 area, along with what seemes like most of the lakes. More practically, I’ve learned my way around the buttons and menus of the electronic doodads, and don’t have to think much about what to push anymore. I’ve begun to develop habit patterns for entering flight plans, managing radio frequencies, and so on, along with more mundane stuff like fueling without spilling fuel all over the wing, remembering to sump the tanks, etc. I’ve developed my mobile office, for days when I still need to deal with emails, server problems, etc, regardless of where I’m at (which is pretty much 7 days a week). And taken goofy in-flight and on-ground pictures.

19.3 hours left on the Phase 1 clock…

[ summary of shop & flight test hours for the last week was entered on this post ]