31st

May

2010

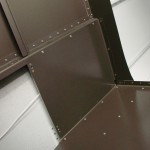

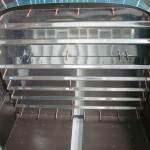

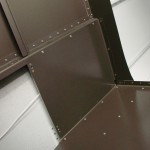

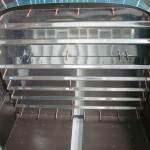

Memorial Day…spent most of the day in the shop after the long weekend of work. The first task was to install the baggage floors, which is done with blind rivets. Easy enough, and made easier by rotating the fuselage 90 degrees…it’s very evident why fuselage “rotisseries” have become popular. I just picked it up at the firewall and turned it on it’s side, moving blocks around to support as necessary. It became much easier to work in once on it’s side, and I will be strongly considering the creation of some apparatus or another to allow this rotation with ease.

Anyway, baggage floors went in, followed by the aft baggage side covers… a bunch of nutplates were also installed along the tunnel and bottom of the baggage wall. This made way for the installation of the baggage wall itself, which is in two pieces. The bottom piece pretty much goes in as is, but the top piece requires measuring and marking of all attach holes, as well as trimming the curve at the top sides. I used my drafting compass to mark the curve, then cut with snips and finished on the disc sander. Slots are cut for the harness cables to pass through, and plastic wear blocks are fit behind those slots.

Fitting the baggage wall takes a series of install-remove actions (including the drilling and installation of 20-some nutplates), but when it is finally in, the forward baggage sides are fit; these are the pieces that cover the flap actuator arms, so they are also installed with nutplates. The pieces have one flange trimmed away at an angle, and the forward vertical flange also should be bent down a couple degrees for a nice fit against the bulkhead. Permanent installation of the nutplates on the bottom edge will come later, after primer and paint.

With the baggage area essentially completed, I set the fuselage back upright to allow removal of the aft top skins, later in the week…these will be removed and the gusset plates drilled to the longerons, then added to the pile for primer. I moved on to the aft seat pans, which need to have the seat bottom hinges fitted. After locating the hinge material, I was able to get the six pieces cut to length and ready for drilling to the pans. I think I’ll fit those hinges, pull the aft skins, and do a prep/prime day sometime this week for the parts that have been completed. Putting the seat pans in place isn’t too far off.

While working on the baggage area, I also masked off the side skins and sprayed paint on the vertical parts of the center section bulkhead, since one side is gold and the other white…paint will hide the obvious marker of a mistake-replaced part!

Hours: 9.1 | Posted in Upper Fuse & Skins |

26th

May

2010

Tech counselor Mike Hilger stopped out to the shop this evening and looked over the progress to date. He nicely complimented the riveting work on the fuselage and we talked about the work going forward with the cabin interior, canopy, aft skins, electrical wiring, engine, avionics, and so on. I was glad to have another set of eyes to verify that the work completed so far is up to snuff, and confirm that my ideas for moving ahead are solid. I’ll be taking one last look at whether to add any wiring provisions under the baggage floors, and then they’ll be riveted down and work can begin on the baggage bulkhead.

Hours: 1.0 | Posted in Fuselage |

26th

May

2010

The finish kit arrived today via Partain Transport…now all the major kits are on site. The box is the biggest yet, due to the canopy and cowling. There is a list of backordered parts that are not present, but it looks like all the major pieces are here, including the wheels and engine mount which weren’t in the box; the driver and a note from Van’s said they arrived at the factory the day my kit was being loaded, so they just wrapped them up (very well) in padded blankets and strapped them in the trailer.

I will admit to feeling a bit intimidated by the finish kit at the moment…it’s a huge box, and reading a new thread last night about canopy troubles didn’t much help! But the plan is still full steam ahead this summer — I’d like to get the canopy done and spend the winter fiddling with systems.

Posted in Finishing |

22nd

May

2010

Riveted the aft deck to the fuselage. Many of the rivets can be reached with various squeezer yokes, but there are several that cannot. Of those several, some proved rather tricky and needed to be drilled out and replaced…the biggest complication was the odd contortions required for bucking; my arm doesn’t bend like that! My left-handed shooting skills are lacking some, which I think is to blame for the bad rivets.

Cleaned up all the drill shavings and vacuumed all the schmutz out of the fuselage.

Hours: 1.8 | Posted in Upper Fuse & Skins |

20th

May

2010

Working on tying up some of the loose ends still floating:

- Finished assembling the brake pedals, including cotter pins on the bolts.

- Installed the steps, bearing blocks, and doublers. Allison helped rivet the steps to the fuselage.

- Enlarged tooling holes in the aftmost bulkheads for snap bushings.

- Finished deburring the aft deck area and riveted the angle crossbeam in place.

- Re-leveled the fuselage, and clecoed the aft deck and spacers in place for riveting.

- Dimpled the baggage floors, and squeezed four rivets on the baggage bulkhead that had been left open earlier.

- Ran a cord through the holes where the rudder cable runs behind the baggage sidewalls, so the cable can be easily threaded through after the walls have been installed.

After cleaning up under the baggage area and spot-priming anything in need, the baggage floors should be ready to go down, and then the baggage wall can be fit. The end-of-year rush should be letting up soon, and I become half-time at work during most of the summer, so I’m hoping to make some decent progress this summer.

Hours: 3.2 | Posted in Upper Fuse & Skins |

9th

May

2010

Sprayed primer and final color on the pile of parts which were etched yesterday.

After they had set up, I squeezed the rivets on the brake pedal assemblies and bolted the pedals to the angle pieces. I think they turned out nicely. The paint thickness added enough to the assembly that I had to turn down the outer flange of the bushings I installed on the pedals…I finished the pilot side before it was time to wrap up.

Need to order those longer bolts for the left step bearing block, so I can get that in and not hold up the baggage floor installation.

Hours: 4.0 | Posted in Upper Fuse & Skins |

8th

May

2010

Etched a small pile of parts in preparation for priming: baggage floors, shoulder harness brackets, upper firewall/longeron gussets, brake pedals, pitch servo bracket, step doublers, aft deck and spacers.

Sprayed the front side of the brake pedals with final color paint (a sand-colored textured Rustoleum rattle can).

Hours: 2.2 | Posted in Upper Fuse & Skins |

5th

May

2010

Searching an escape from the treadmill that is life, both at home and at work, in these last few weeks of the season, I headed out to the shop for a bit of time on the project, and accomplished a few little tasks:

- Trimmed the holes in the aft end of the inboard baggage ribs, which I had neglected to do before riveting the tailcone on. A burr and sanding drum on the Dremel made quick work of this. Smoothed with a scotchbrite pad and spot-primed.

- Removed the aft deck and spacers, deburred all holes and edges. Deburred the drilled holes in the aft end of the longerons.

- Deburred all holes and edges of the baggage floors.

I have a small pile of parts ready to be primed, then the aft deck and baggage floors can be riveted in place, and construction can continue.

Looking ahead to the electrical wiring, I also removed the snap bushings from the tunnel at each bulkhead, and reamed out the slight lip on the inside diameter, to obtain the maximum diameter for wires. The 1/2″ step on a Unibit worked perfect for this. These bushings were then reinstalled. Curious, I tried to stuff one full of wire, and found I could pass (5) pieces of RG-400, with room for some smaller wires in the center and at the perimeter, or (3) pieces of RG-400 and (4) pieces of shielded 14-4, again with some room left over for smaller wires. What does this mean? Not much right now, but as I work through my wirelist, it should help with planning.

Hours: 1.6 | Posted in Upper Fuse & Skins |