Let the fuel bills begin

Not perhaps the most auspicious of milestones, but I did put the first avgas money into the project today…5 gallons worth into a new blue fuel jug, for the sake of fuel system testing.

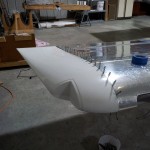

But first…most of the day was actually spent on or near the wingtips. I spent awhile shaping some foam ribs to go inside the tips, to strengthen, eliminate oil-canning, and hold the proper shape. Once I had one side looking good, I marked the spot of each rib, traced them on fresh foam, and cut a matching set for the other side, which provided a good starting point. After setting the location of each rib for proper shape of the tip, I mixed up some flox and buttered the edges, set them in place, and pinned the tips back to the wings to hold the proper shape & alignment while the epoxy cures. I’ll pull them tomorrow, add more flox to fill in any gaps, and lay a strip of glass tape along the edges of the larger foam rib, for good measure. (No photos of this because I was covered in foam dust and epoxy.)

Wingtips curing nicely, I moved on to the lenses which cover the lighting “bay” in each tip. I remembered to bring the replacement lens this time, and I had dropped the belt/disc sander off the other day, so all the parts were in place. It’s nothing too difficult, just a lot of repetitive and time-consuming fitting, sanding, filing, fitting again, and repeating the whole process. Since it fits a curve at two points, each bit you take off changes the fit of the rest of the lens, so it took awhile to get it right. Once satisfied, I drilled a #40 hole at the corner, top & bottom. Clecoed to test fit, then enlarged to #27 for a #6 screw, removed, and drilled/countersunk holes for nutplates. Those will be installed tomorrow when the tips come off after the epoxy cures.

Moving inboard a bit, I removed and cleaned the lenses for the landing & taxi lights. They were quite dirty on the inside surface, since the wings were stored leading-edge down in the cradle. Shiny and clear again now, though.

Cut some lengths of acrylic tubing from a 6′ piece I had ordered a while back, and smoothed the ends. This will become a fuel dipstick for checking the tanks.

On to some engine work in preparation for an eventual first engine start…

- Removed the paper towels that I’d stuffed in the fuel servo inlet to keep out bugs/etc.

- Used a syringe to apply some Mouse Milk to the exhaust ball joints.

- Connected the computer to each Pmag in turn to verify the timing (also cross-checked with the indicator lights on the ignition body), and make sure that the advance was limited to the “basic” setting (35 degrees). Once the engine has been broken in, we’ll dial this up to the more advanced 40° setting, which should help the engine run more efficiently. The two ignitions are timed nicely together, and they are timed to 1° after TDC, rather than TDC directly. Based on the manual, I’m going to leave this be for now, since they do suggest that it be up to 3 degrees after TDC for lightweight props, which mine is. We can tweak later if necessary.

Later on, I drove down to the fuel pumps to fill up the aforementioned can with fuel. Poured some into each tank (BTW, I hate the newfangled gas nozzles that you have to push down against a spring to keep the fuel flowing…and their vent inlets are so tiny that the flow rate is pathetic), sloshed it around by rocking the plane, then drained it back out again — the idea being to get as much junk out of the tank as possible. Filtered it back into the can, and poured from the can back into each tank. Sumping into a tester showed clearer fuel this time.

Disconnected the fuel line from the servo inlet, but I didn’t have the fittings with me to extend it anywhere useful, nor a measured container to pump fuel into, so I just capped off the line and servo inlet for another day.

Three project visitors today; Art (Lancair) from the airport brought his Australian pilot friend (Jabiru) around to check on the progress, and Bob Collins (RV-7A) dropped in later in the evening to chat and take a look, while on a flight around his test area. As the sun was setting, I caught this neat picture out of the hangar door, with the cloud shadows… A good day.