18th

April

2009

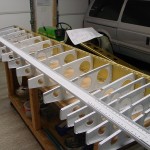

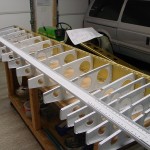

Finished dimpling the wing skeletons, and enlarged the rear spar dimples with the deburring bit as described in the manual. Checked the left wing in its fixture, re-stringing the line along the spar rivet row, and hanging the plumb lines at inboard & outboard ends. Leveled, measured and adjusted until the twist was zero, then dropped the LE assembly on top and clecoed in place.

Riveted the assembly to the spar, and managed to use all solid rivets. Going in, I was convinced that I would end up using blind rivets on many of the ribs (as many 7 builders do, with Vans’ approval), but the 9 wing design must allow more space, as I didn’t have any trouble. I did need all three of my universal-head rivet sets (straight, offset, and double-offset) in various places, and the third rib from the inboard end is a two-person job due to the reach. (Thanks to father-in-law Bob for help driving those rivets!) None needed to be drilled out, and the rows of skin-to-spar rivets went quickly with the squeezer. Left leading edge is installed!

Next will be the right LE to spar, then deburr/dimple/prime the wing skins. Still need to get a flaring tool so I can flare the ends of the tank vent lines in order to seal up the tanks.

Hours: 4.3 | Posted in Skin Panels, Spars & Skeleton |

17th

April

2009

Finished the riveting of the leading edges; worked the right assembly in the cradle, then stood both L & R on end to reach in and drive the last 3 rivets at the nose of each rib. Both came out nicely.

Primed the skin countersinks on the spar flanges, as well as dressed out & primed several bucking dings on the webs. Started dimpling the wing skeletons…lots of holes! Got a little more than halfway through.

Hours: 3.3 | Posted in Skin Panels, Spars & Skeleton |

6th

April

2009

Finished deburring the left wing, and got most of the way through the remaining holes on the right wing. Should be done soon, then dimpling the skeleton can begin.

Hours: 2.0 | Posted in Spars & Skeleton |

30th

March

2009

Wing skeleton 5/8 deburred…got the outside edges of all ribs & spars, and inside edges of bottom left wing before the batteries ran out in the deburring driver.

Hours: 1.7 | Posted in Spars & Skeleton |

7th

February

2009

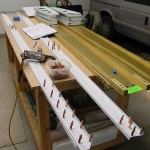

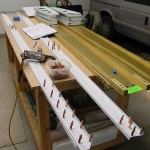

Evening session…pulled the leading edge assemblies off the wings, followed by the J-stringers and skins. That’s a metric boatload of holes and pieces to be deburred, dimpled, and primed. I’ve read that the mil-spec on riveting indicates that holes which are dimpled (aka “form countersunk”) are not required to be deburred, but it seems the common practice is to deburr the holes anyway, and that’s what I’ve been doing so far. I suspect I will need to order more primer to finish this off…maybe it’s time to bite the bullet and order the gallon can instead of the quart.

After everything was pulled apart, I deburred the holes in the spar web (LE rib-to-spar holes), and countersunk all the skin-to-spar holes to receive the dimpled skins. Lotta countersinks. Finished off by blowing the shavings out of the skeleton and giving the shop a good sweeping.

Hours: 2.5 | Posted in Skin Panels, Spars & Skeleton |

2nd

January

2009

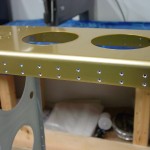

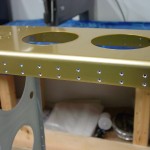

Completed the riveting of the wing skeletons by attaching the right rear spar to the ribs, and the forward rib tabs to the main spar…easy. I also took a trip to the store for some plywood to reinforce the wing jig, and built that. Ended up making a second trip, too, as I underestimated the amount of threaded rod I’d need to rig up the angles at each side. The threaded rod with nuts at each end allows for an easy adjustment of level.

Building up the jig went easily, if not necessarily quickly. I followed the general lead of Smitty, who details the dimensions and such he used in his build log. I built two jigs, so that both wings can be built at the same time. They’re also freestanding, rather than the plans type which have a post running from floor to ceiling; this was essential for me as I need to be able to get the overhead door open, and the posts would interfere. It’s basically 4′ legs, 5′ uprights, and 139″ on the beam, with reinforcing sheet panels (I used some cheap 1/4″ chipboard), angle braces on the uprights, and lots of screws. The arms are made from leftover steel angle bracing from the overhead doors I removed from the shed that we tore down to make way for the new garage…proof that saving everything has its merits! Hung the skeletons on the jigs.

Fixed the heater, as well. The check-valve device turned out to not be the culprit, as the problem continued after I took it out of the line. Pulled the access panel off again and took a good look inside. I saw signs of arcing on the side of the spark igniter arm (two metal rods that stick in through the burner box to create the spark in the jet of gas for ignition). That tipped me off to the trouble; turns out the igniter had a smaller gap to the nearby burner than it did to its own ground rod, which was causing the spark to jump to the burner, rather than the igniter gap–which put it largely outside the gas jet. I removed the igniter assembly and bent the two rods away from the burner a bit, then reinstalled. Perfection. It lights off every time now that the spark is happening in the gas jet, rather than jumping to the metal of the burner.

Hours: 5.0 | Posted in Spars & Skeleton |

1st

January

2009

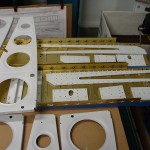

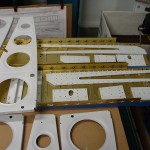

Started out with a pile of primed parts and spars. Lesson one: remove any blue tape used for masking as soon as possible…I covered the gaps of the upper and lower flanges with tape to keep metal chips from the countersinking from falling in, and ended up spending a fair bit of time removing it, and the adhesive goo it left behind. (Yes, this was the blue, easy-removal “painters” tape.) A heat gun helped more of the adhesive come off with the tape, and acetone cleaned up the rest.

Riveted the rear spar components together to form complete spars; careful attention required here to avoid filling any holes needed for other pieces later on. A close look at the plans in the area of the outboard aileron hinges revealed a previously overlooked detail; that the outboard rib is attached to the rear spar with flush rivets, so the aileron bracket can fit over those rivets. Dimpled the outboard rib, rear spar, and spar doubler on each wing.

Clamped the left main spar to the bench and attached the ribs one at a time from the outboard end inward, which worked well. Once those were in place, I riveted the front tabs of the ribs which are beneath the fuel tanks to the countersunk holes in the spar. (There’s no specific mention of this in the instructions, but it’s clear from the plans what needs to be done here…whether this was the best time to do it will be decided later.) Clecoed the rear spar to the ribs, and riveted that on–all those rivets are squeezable, which is nice. The right wing has nicer rivets, as I changed the way I was using the rivet gun by lowering the pressure at the compressor regulator, and opening the restrictor on the gun fully. This seemed to provide a more even series of hits than a higher pressure dialed down at the restrictor. (The theory is that because the restrictor controls flow, not pressure, the first hits of the gun are at full line pressure–since the pressure has time to equalize across the restrictor orifice–with subsequent hits at a lower power due to the restricted flow.) Finished the right main spar-to-rib rivets, but still need to squeeze the rib tabs and rear spar attach.

Also getting a little frustrated by the heater…works great when it fires, but it fires very randomly, with many failed ignitions. I’ve checked input pressure and manifold pressure with a simple U-tube manometer, and both look OK. I’m wondering if the saftety check-valve gizmo installed in the line (it came with the CSST that I used to go from the valve to the inlet connection; it’s supposed to close in the event of a breakage of the flex line) is causing a problem. I might remove that from the line and see what happens, and will also double-check the spark ignitor, but it appears to function correctly.

Hours: 7.5 | Posted in Spars & Skeleton |

31st

December

2008

Cleared the priming hurdle today with about 7 hours in the shop (though some of that time wasn’t build-related). Hung up plastic from the tracks of the big garage door, and a piece on the floor, to create a priming booth about 9′ x 8′. Set a strip of plywood on a couple sawhorses inside for a priming table, and held the plastic down with some 2×4′s.

Actually worked pretty well, though a bit slower than priming outside, due to drying times. Not sure if that’s more due to the lower temps (I run the shop temp at 45-50 when I’m working in there), or the lack of air circulation. I settled into a routine of doing the first light coat, waiting a bit for it to tack, laying the second, slightly heavier, coat, then opening up the plastic wall and turning on the heater fan (with heat, if the temp was getting low) to dry the pieces, before flipping and spraying the backsides with the same process. Got all the rear spar parts and main ribs primed (whew!), and deburred the holes in the spars during downtime. Everything should be cured nicely tomorrow, paving the way for skeleton assembly.

In an earlier post, I wrote that my goal was to have the skeleton complete by the end of this month (a revision from my original goal of Christmas). Didn’t quite hit that target, but I did come close…ought to have it in the bag this week. I bought lumber for the wing stands today as well, so after getting those built, it’s on to skins, J-stringers, leading edges, and tanks. New goal…tanks complete by my birthday (March 1)? Not sure if that’s realistic or not; Smitty logs about 50 hours for each segment of each wing (prep, skins, tanks; I believe he built his wings separately), plus another 50 each for ailerons & flaps.

Hours: 5.0 | Posted in Spars & Skeleton |

30th

December

2008

Long session of rib prep…finished drilling, deburring, and etching/scrubbing all the remaining wing ribs for both wings. Bought some plastic yesterday to hang up for a priming area; with that, and some large cardboard leftover from a fridge box, ought to be able to kludge something up and move on to priming and assembly, assuming the primer will dry in the cool shop temps. Wing jigs are on the horizon for later this week, so started to shuffle the shop around to see where they’ll fit. I need to build some shelves and get things off the floor on the east side, as well.

Hours: 4.9 | Posted in Spars & Skeleton |

29th

December

2008

Received a reply from Vans:

These small holes won’t make any significant difference to strength, so just clean them up and move on.

Both holes can be used for pitot/wire etc, but only one needs to be enlarged. The other is already full size.

So I’ll deburr those extra holes as normal, and forget about them.

Posted in Spars & Skeleton |