26th

June

2011

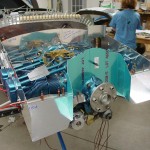

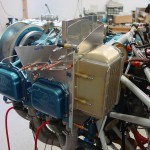

Worked on various little projects around the plane:

- Finished install of cabin brake lines. Torqued and marked.

- Bolted rudder pedals in place. Tried the middle holes, but with the seat put in, they’re too close for me, so moved them to the forward holes.

- Messed with ignition leads to see how much too long they are (some are just right, others are several inches too long).

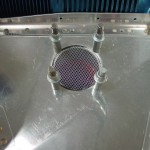

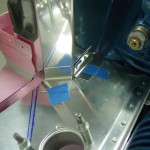

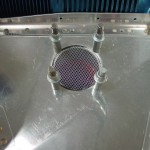

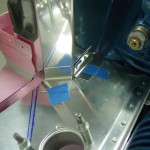

- Cut pieces of screen for the second heater air takeoff, and the cabin fresh air vents. Installed the vent screens between the scoop and the duct. RTV’d the heater takeoff screen and clecoed the flange in place to cure; this’ll get riveted next time.

- Played with routing for the left heater feed, which comes off the baffle inlet ramp. Discovered that there is enough room between engine and cowling to run the SCAT along the bottom of the valve covers with adel clamps. Will need longer screws to allow attachment of things like these clamps, and ignition wires, to the valve cover screws.

- Fabricated and installed a bracket for the purge valve cable.

- Installed new lockwashers, torqued and marked the engine case bolts along the top that were removed for installation of baffles & brackets.

- Figured out how to install the Reiff preheater power harness along the top of the engine, and did so. Ran the cable to the sump heaters through the same grommet as the fuel supply to the spider.

- Installed clamps to secure the transducer-spider fuel hose.

- Started work on finishing up the engine side of the thermocouple wiring. I’m planning to leave these wires long and double them back, leaving plenty of extra length, as they would be a pain to replace in the event that one needed to be trimmed and no extra length available.

Hours: 5.5 | Posted in Engine, Plumbing |

24th

June

2011

Started installing brake lines tonight; put in the elbows at the calipers and fit those lines, along with the right-side cabin elbows, lines, and reservoir tee.

Hours: 1.5 | Posted in Plumbing |

23rd

June

2011

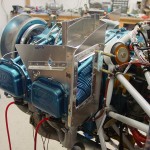

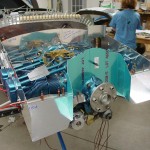

More work on FWF stuff today…routing the purge return line behind the baffles, then re-routing it to clear the oil filler tube. Reworked the CHT/EGT wires on both sides to clear other items like the purge line, purge control, and oil cooler hoses. Fit the oil cooler hoses to make sure everything had clearance. Installed another fistful of adel clamps. Ran the purge control cable through the firewall and baffles.

Updated the FWF to-do list, but most of the components are in place now; much will be removed & reinstalled, but at least things are fitting together.

Brake lines and harnesses have arrived.

Hours: 2.8 | Posted in Engine |

21st

June

2011

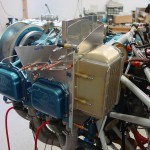

Mostly baffles again today, but I think I can see the light at the end of that tunnel. Finished up the forward ramps, trimmed the inner pieces, and drilled the clips that hold the vertical segments in position. Pulled them apart to deburr and rivet. Fit those back to the engine, and pulled the aft baffles to clean up, deburr bolt holes, and install the takeoffs for Pmag blast tubes, and purge line grommet. Refit the aft baffles to the engine. Will need a grommet for the purge valve cable yet, and to figure out how to route the cord for the engine preheater. Need to pick up some screen for the second cabin heat takeoff, then that can be riveted on. Baffle metalwork is nearly done, except for all the trimming at the top.

One bit of fun: installed the “EXPERIMENTAL” placard…doing little cosmetic-type things like this makes it feel like the end of the project might be attainable.

The Bill of Sale arrived today from Van’s, so I can start plugging through the registration paperwork. Also got confirmation on my prop order today, and (re)ordered the ELT from Van’s, after checking that they actually had stock–cancelled the order at Spruce, where I’ve been on the waiting list; they have no idea when more are coming. Harnesses and brake lines should arrive this week, as well. Need to order the prop spacer kit.

Hours: 3.8 | Posted in Cowling & Baffles |

19th

June

2011

Or, more accurately, ‘n’ more baffles… I did do one non-baffle thing today, which was to mount the capacitor for the SD-8 backup alternator next to the relay, now that I have the correct size adel clamp. The only cabin-side part of that system which can’t be pre-mounted is the regulator, since it comes as a package with the alternator. There is a dimensional drawing for it, so I could install the nutplates and hope the drawing is accurate… (Trying to be cheap and not buy it until a future upgrade date.)

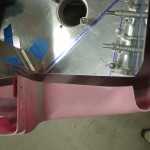

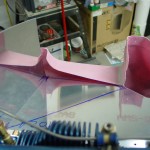

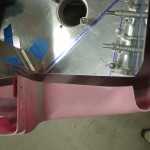

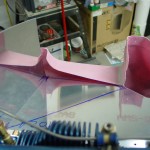

Then, back to baffles. It doesn’t look much different after a day’s work, but the inlet ramps have been bent to fit, the forward corners formed, and the conical-bend filler pieces fabricated and drilled. Trimmed the front inside corners for clearance to the flywheel and alternator belt. The ramps and stiffeners have been riveted, and holes made for the LH cabin heat take-off, and the alternator blast tube. Locations marked for the Pmag blast tubes, which will be drilled when the rear baffles come off again. The inlet ramps were trimmed to fit the cowl, with a 1/2″ gap between cowl and metal, which will be bridged by the airseal fabric.

With the inlet ramps in good shape, attention turned to the vertical pieces behind the flywheel, which took more iterative fitting to get the angles right. Made and drilled the attach clips for the right side, and cut the stock for the left before calling it a night. Need to look at my saved baffle reference links to see how the vertical piece is trimmed, as it’s not clear in the directions or included photos whether it’s trimmed back to the length of the ramps (which would make sense from a vibration standpoint) or left longer.

Hours: 6.5 | Posted in Cowling & Baffles |

16th

June

2011

Deburred the front lower baffle pieces and finished fitting them to the engine. Then, read the next page of instructions several times and studied all the diagrams until it made sense how this is supposed to fit together at the intakes. Wrestled the lower cowl into a place where I could mark some guide lines, and made some initial trims. After a couple cycles of fitting and trimming, I have the inlet ramps trimmed to a point where the lower cowl can be put on. The ramps are still longer than the end goal, to allow for progressive trimming to get the fit right. Need to do more reading & picture studying to understand the interface between cowl, airseal fabric, and baffles.

Hours: 2.9 | Posted in Cowling & Baffles |

14th

June

2011

My tech counselor, Mike Hilger, stopped out this morning to take a look at the project. I’d asked him to come and take a look before I get to the point of buttoning up the forward top skin, since after it’s on, the only access to that area is from underneath the panel. I’m still going to wait awhile to put that skin on, since there are more things to be done up there (incl. brake lines & rudder cables). I also wanted him to check out the FWF work I’d done so far. Based on his comments, I’m on the right track and doing good work. We talked about a few items and next steps for baffles, cowling, tips, and so on.

I let the folks at work know today that I’m hoping to take a couple blocks of time off during the summer…perhaps one early and one late, to do some hardcore shop time. I feel like I can keep pretty good momentum going and get a lot done with a few full days to work.

Also called to request a bill of sale from Van’s today; they sent me a couple forms to fill out and return, then they’ll send it out. Then, I’ll be ready to submit the FAA registration paperwork (my N-number reservation renewal is up at the end of July, so it makes as much sense to register instead of renewing this year).

Hope to order brake lines & harnesses tomorrow, and hopefully will confirm with Catto by the end of the week.

Hours: 1.0 | Posted in General |

13th

June

2011

More work on baffles: finished fitting the right rear and riveted it together, including the flange that will feed the right heater box. I need to figure out where to put the flange for the left heater, too, and there will be several blast tube flanges to mount, for mags and alternator.

With the rear baffles in place, the front sides were fit–those are two easy pieces. Next step was the brackets that mount to the engine case bolts. The rear bracket required a slight tweak in the injector line for the #4 cylinder to provide clearance there, and both engine lift straps had to be removed, since all the bolts are now in use to hold something or another.

Finally, worked on initial fitting of the bottom front sections, which form the bottom of the inlet ramps. Worked out most of the kinks (again many fit-mark-remove-tweak-repeat steps) before calling it a night.

Hours: 3.1 | Posted in Cowling & Baffles |

12th

June

2011

Hours: 4.1 | Posted in Cowling & Baffles |

11th

June

2011

More work on baffles, fitting and drilling the rear left segment and oil cooler mount. Almost ready to rivet.

Hours: 4.4 | Posted in Cowling & Baffles |