30th

January

2012

Removed the clecoes around the firewall perimeter, along with the lower cowling side hinges and shim strips. Primed these and the camloc strips in preparation for riveting the firewall (after inserting sealant).

Removed the empennage; they likely will not go back on until final assembly.

Torqued & marked the rod-end bearings on the elevators & rudder.

Riveted the VS forward attach bracket to the VS, and riveted/bolted the rear attach angle to the fuselage aft deck.

Drilled/countersunk/dimpled the VS tip; set that aside with the HS tips to await fiberglass finishing.

Countersunk the emp fairing attach holes for tinnerman washers. Drilled and riveted the emp fairing nutplates on the VS. I’d like to get the entire empennage group tips smoothed, sprayed and riveted on, and take them to the hangar to stash with the wings.

Torqued & marked the brake line connections at the calipers. The brake system could be filled & bled at any time.

Hours: 3.6 | Posted in Wing & Tail Joins |

29th

January

2012

Allison joined me in the shop for a bit to finish removing the tape gunk from the empennage fiberglassing adventure. While she worked on that, I sanded the micro and shaped the edges of the emp fairing. After fitting it back onto the plane, I’m pretty happy with the fit. Now, I’m going to use this (and the emp tips) as a learning canvas for fiberglass finishing. I have a box of PPG stuff here that I’m planning to use, which I chose because it seemed to be the most well-documented on the forums and build logs.

I also drilled the HS tips to #30, dimpled the skin, and countersunk the fiberglass. These are ready for finishing, then attaching. The goal with the fiberglass stuff is to get it to an acceptable level of finish and wearing a protective coating. If it needs to be dealt with further, I can revisit it before paint (or let the pros make it shine as part of the pain process).

With the fiberglass dust (ack) cleaned off the workbench, I pulled the clecoes from the baffle airseal strips and installed the large-head pop rivets that hold it in place.

Finally, I installed the latest version of the EFIS software from AFS. The problem where the screen blinks durin initialization when displaying the VP-X status page has not been fixed. I pulled the config files to load into the computer and update some things. (Hint: Linux works better than Windows for editing these files, as the line breaks display correctly…no surprise, since the AFS box runs Linux internally…)

I’ve also been working on the paperwork side, having built an InDesign project and templates for the POH, and compiling the “best of” from several existing POH’s that others have shared on their websites. There’s lots of specific information to research and fill in, and plenty of stuff yet to write. Being a layout nerd and a perfectionist, it’s possible to pour hours into this part, too.

Hours: 4.5 | Posted in Cowling & Baffles, Electrical, Wing & Tail Joins |

28th

January

2012

Decided to apply the N-number decals tonight. These are intended to be pseudo-temporary markings, until she gets painted someday, but they’re permanent for now.

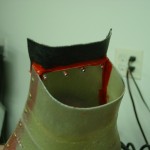

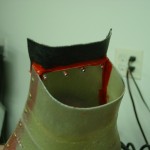

Removed the airseal from the baffles, cleaned them, then ran a bead of red RTV along the baffles, and clecoed the airseal back in place. I’ll let this cure overnight and install the baffle rivets tomorrow. Also fitted the airseal to the top of the FAB.

And made up some pieces of airseal that will cover the spark plug access holes for the rear cylinders.

Hours: 1.8 | Posted in Cowling & Baffles |

26th

January

2012

It’s been a but more than a year since my engine was built, and the protections applied at the build shop were said to be good for 12 months. I’ve been careful not to turn the engine, and have kept it’s openings mostly plugged, but I asked the kind folks who built the engine up at Aero Sport Power what measures I should take to prolong the preservation, given that it will likely be several more months before the fires are lit. Having procured the necessary items, I carried out their recommendation tonight:

- Pour 3 gallons of oil into the crankcase. They said this could be automotive oil, as it’s only there to cover and protect, not lubricate for flight. I put in conventional (non synthetic) Valvoline.

- Cap off the breather and exhaust stacks. I had a plug that fit into the breather hose, and I wrapped the stacks in plastic & tape, since I don’t have any plugs that large.

- Cap off the intake; this is already done, before I started doing any fiberglass work on the FAB & intake scoop.

- Insert dehydrator plugs and keep them dry. I looked around and found some that the crystals can be taken out of and dried. Make sure to ask that, as there are several places selling 14mm ones that are sealed, alongside the regular reusable 18mm versions.

I’ve been doing final reading on brake fluid & seals, and I decided to change out the caliper O-rings, since the stock Buna-N ones will deform in the 250* range. There have been cases of brake fires on RV’s and similar aircraft before, so many guys are replacing the 5606 fluid (flash point in the 200′s) with the more modern 83282 (flash point in the mid 400′s). Synthetic ATF is another option, which has specs similar to that of the 83282. It’s also become common to change out the O-rings with Viton, which is rated to 400*. The downside to Viton is it’s poor low-temperature performance (-15*). Since I do plan/hope to fly in the winter, I found some flourosilicone O-rings at McMaster, which have the same high-temp rating as Viton, but are also rated to -75. (They’re listed under “military specification o-rings,” p/n 8333T255)… a little pricey at $6.25 for a 2-pack, but that’s small potatoes.

The install couldn’t be easier: remove the caliper, pop out the piston, remove the old O-ring, clean up the piston & bore, lube the O-ring and insert it, then slide the piston back in place and re-assemble. Done.

Finally, the mixture linkage has been bugging me for awhile; even with the higher hole I drilled in the quadrant lever, it wasn’t confidently hitting the stops on the fuel servo before hitting the end of the quadrant throw. (Yes, I tried a bunch of different arm angles.) To solve that, I pulled the mixture arm off and drilled another bolt hole a bit higher than the existing one, then reinstalled. Works perfectly now, the stops are hit before the quadrant lever runs out of travel, and the throw matches that of the throttle lever.

Hours: 1.9 | Posted in Engine, Gear & Fairings |

21st

January

2012

Installed what should be the last firewall eyeball, for the alternate air control cable.

Fooled around with a piece of ceramic batting, to explore how it would work to fit it on the cabin side of the firewall. I wish it were stiffer, the stuff I ordered is sort of floppy. I think it would stay in place if cut to the right dimensions and backed with metal foil. I may do this yet, but still waffling. Plenty of planes flying without it… If I do decide to put it in, I want to do it before the top skin is riveted.

Attached the cable-end fitting to the alternate air slider assembly, then drilled the assembly to the airbox. Made spacer strips for each side so the cotter pin wouldn’t rub on the fiberglass. Riveted the slider to the airbox, with an RTV “gasket” to the hole in the bottom of the box.

Cut the filter holder clips and drilled them to the airbox top; deburred, countersunk, and installed with nutplates. Riveted the airbox top to the glass bowl, again with a bead of RTV around the perimeter for an airtight seal. Temp fit the whole airbox assembly to the fuel servo.

Hours: 4.5 | Posted in Engine |

7th

January

2012

Received the prop spacer, crush plate, and bolt kit, and test-fit that to the engine. Deburred the rear spinner bulkhead and test-fit that as well, along with the entire cowling, to see how close I came out on the cowling/spinner fit with my PVC spacers — looks like it will work.

Now that the emp fairing epoxy/micro sludge has finally set up hard, I went to remove the packing tape used to prevent the epoxy from adhering to the aluminum, and found that the plastic layer of the tape peeled off, leaving 90% of the adhesive behind, stuck to the plane. Ugh. Acetone doesn’t do anything besides make it gummy and smear it all over, so I’ll have to pick up some other solvents from the store and see what will remove it. It doesn’t scrape well, but mechanical rubbing (with a finger) removes it slowly in little balls. Clearly, some better tape is in order for future layups.

Hours: 1.5 | Posted in Cowling & Baffles |