First step step

Hours: 3.2 | Posted in Upper Fuse & SkinsMatch-drilled both of the top skins to the structure, except for the longerons — since the underlying holes have already been drilled & dimpled, I’ll just run a reamer through all those holes in the top skins after they come off. Also match-drilled the 710 bulkhead to the aft deck.

Browse the manual, what’s next? Steps…I’ve read this is tricky and I can see how it could be. The first step was to trim the end of the step tube, which was too long, and hit the baggage rib before the flange seated on the skin. The flange was about 1/4″ away from sitting flat, so I trimmed 1/4″ off the end, and somehow ended up 1/8″ short. Sigh. I’ve heard that there is some variation in these things–some too short, some too long, so I’m not going to worry about it, and may fabricate a spacer to bring the plastic block out the extra 1/8″.

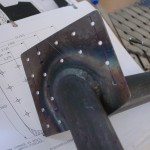

Patience is certainly required, as there is much repetition of the bend-fit-remove cycle, trying to get the step flange to mate nicely with the side skins. After several tries, including some filing and a trip to the grinding wheel, I finally got a decent fit. Once fit, I pulled the step off and laid out two holes in diagonal corners, drilled, then back-drilled to the fuselage and clecoed in place. Marked the centerline of the rib that one row of rivets picks up, and removed again to lay out the rest of the hole pattern. I used only 4 rivets in the rib row, instead of 5, as at least one of the 5 would have been drilled through half of an existing skin rivet. With four, I was able to split the distance between the five skin rivets under the flange and have good edges distance on everything.

Several more fit-remove cycles were involved in fitting the plastic block that fixes the inner end of the tube to the rib, since my angle drill is too fat to fit in there nicely with the step tube there. I marked the hole with a #11 bit, then removed and drilled, before putting it back in place. For now, I bolted it to the rib, but did not drill the hole through the step tube, in anticipation of a spacer being fitted behind the block later.