Pulling up the pants

Airport-hopped for another 3 hours of transition training this morning, including a climb to 9500MSL…even on a rather hazy day, what a view; 184kts (~212 mph) groundspeed was impressive, too. Flying a panel with a traffic system really highlights the fact that there is a lot of traffic out there that we never see — even when we know it’s there, since it’s on the display, and even when it’s relatively nearby. And autopilot…made cruise flight and descent planning a whirl. I’ve managed to put the wheels on the ground a couple dozen times now at a bunch of different airports. A bunch of stalls (power-off and power-on…that deck angle is impressive) and airwork as well. 6 hours left on the requirement.

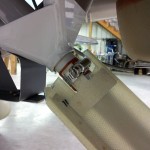

Back on the ground, the push to complete wheelpants & leg fairings continued. I got the wheelpants both mounted up, nutplates installed on the inboard bracket, and just using locknuts for now on the outers (miniature nutplates on order). Safetied the outer bracket bolt, and found one wheel cotter pin that hadn’t been bent. Drilled access holes for tire inflation & pressure check, and plugged with stainless hole plugs.

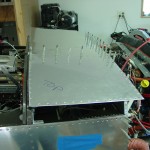

Fabricated metal T’s out of .025, to reinforce the tabs at the top of the gearleg fairings, and installed those before installing the leg fairings. Also removed the nose leg fairing again to cut slots for a hose clamp, install the metal tab T’s, and reinstall. The upper clamp should prevent the leg from vibrating around; the plans leave it floating free to rub on things, though it’s pretty solid as it was. The nose leg is easy to align with string, so I did that and buttoned up the nose gear again. The mains still need to be aligned, but are otherwise done for now (until intersection fairings show up).

I decided that I’ll move the fire extinguisher between the seats, aft of the roll trim lever, for increased legroom, and to position it away from the probable location of any fire. I’ll secure the bracket to the tunnel cover between the seats; I need to find some spacers, though, to raise it up, since my extinguisher bumps into the roll trim knob when all the way down flush on the cover.

Located the seatback adjuster brackets and hinges, and installed the hinges to the back of the seats. I’ll paint the brackets to match the interior colors.

Talked to the shop on the field after lunch, and though they weren’t thrilled about it, they did agree to try and find time to do a transponder check, and weigh the plane — if they have time — on Monday morning. They want to do it in their hangar, not mine, which means of course, that after I drain the fuel out, I get to pull it over there with the towbar…fun. If they don’t have time for the weighing, it’ll be double the fun, since I’ll get to pull it over there & back twice.

Once we have a weight, I’ll be able to submit the inspection paperwork and get the ball rolling. We’re close, and I’m looking forward to having it in the air.

Hours: 6.8 | Posted in Endgame, Gear & Fairings | Comments Off