28th

September

2009

Started to putz with the fuselage by laying out the firewall and clecoing the various angles, stiffeners, and such in place. Some searching was necessary to find all the little bits, and I’ll have some doublers, angles, and reinforcing plates to fabricate. I’m thinking that I will install the fuel pump doubler plate, even though I plan an injected engine–one can never tell what the future might hold, so best to be prepared.

Hours: 1.2 | Posted in Bulkheads |

28th

September

2009

Some odds and ends on the ailerons…put torque-seal on the bracket bolts, short pushrod ends, and put the ailerons back on the wings for safe-keeping. Spent some time tidying the shop as well. Still haven’t primed the long pushrod parts, as it’s been an insanely busy week.

Hours: 1.0 | Posted in Ailerons |

21st

September

2009

Prepped the long aileron pushrods for primer, along with touching up spots on the wing needed to be spot-primed after assembly. Greased and installed the aileron bellcranks; torqued the bracket-spar bolts, and the pivot bolts. Also replaced the 4 bolts on each aileron that may have been overtorqued with fresh bolts & nuts. The removed ones showed no signs of distress, but better to be sure than wondering when it comes to control surfaces.

Hours: 2.4 | Posted in Ailerons |

13th

September

2009

Pulled in the wing conduits; a painless–if rather loud–process.

Hours: 0.3 | Posted in Accessories & Mods |

12th

September

2009

No real work on the project today (a large portion of which was dedicated to a choir “retreat”), but I did research and order some parts. Various hardware parts (bolts, nuts, washers, etc) from Van’s, and a couple tubes of grease (Aeroshell 33, billed as a “universal airframe grease” good to -100*F; and Aeroshell 22, which is listed for use in stuff like wheel bearings; full catalog of Aeroshell greases) from Skygeek.

Posted in General |

11th

September

2009

Spent some time monkeying with the internal workings of the wing. Reamed the bellcrank bushings and turned them down to the proper length, then assembled both bellcranks. Some of the bolts that came with the autopilot servo install kit are too short, so it looks like I will need to order a few longer bolts…add to the list. I also need to look up what an appropriate grease is for the bellcrank bushings–the manual says “your favorite multipurpose grease.” The stuff I have says it is rated to -20F. Presumably, the possibility exists that the thing could be colder than that at altitude, so is it appropriate? (Of course, my truck is lubed with the same stuff, and has worked fine in temps colder than -20F…) I’m sure there’s a common aviation grease of some sort for this purpose, too.

Cut and drilled the pushrods, making them a bit longer than plans, as I’ve heard of some people wishing they had, when they had a hard time obtaining the required amount of thread engagement on the rod ends. After dosing the insides with primer, I assembled the short steel pushrods (riveted per plans), but the longer aluminum ones still need to be primed & riveted. Also had a bugger of a time locating the jam nuts for the rod ends (hint: look in the bag marked “spar bolts & misc”).

Temporarily put the bellcranks in the wings (I didn’t realize before that the bellcrank brackets had to come out, as the center bolt is too long to insert with the bellcrank in position.) and set the pushrod length using the straightedge aligned with the tooling holes and the bellcrank alignment tool. I’ll have to get the protractor out and see if there is enough aileron travel the way it is, or if the spar pushrod holes need to be relieved to allow more clearance; the pushrod swings up/down and in/out as it moves through its travel.

Hours: 6.2 | Posted in Ailerons |

11th

September

2009

Hours: 2.8 | Posted in Flaps |

10th

September

2009

Fit the top skin and leading edge skins to the left flap, and riveted them in place. Made a couple light smilies when I lost track of the gun during the vertical riveting. Sigh…but no big deal.

Tonight’s session also saw the passing of the 500-hour mark on the build. It doesn’t seem like that much time, but I have been working on the project for over two years (I started in earnest in May, 2007). This means I’m somewhere between 1/4 and 1/3 of the way done, based on hours. So, 4-6 more years?

Hours: 2.5 | Posted in Flaps |

8th

September

2009

Hours: 0.4 | Posted in Flaps |

7th

September

2009

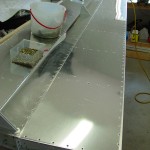

Almost finished the right flap — just a portion of the trailing edge rivets remain. First, the top skin is riveted to the spar & ribs in a manner similar to the ailerons. The tungsten bar is great for this–it’s small enough to nest into the spar channel and tuck into the ribs.

After riveting the top skin on, the flap is flipped topside-down on the table and weighted in place, then the bottom skin riveted to the spar & nose skin. This is a tight operation, squeezing inside the flap with the weights/clamps/boards in the way. Finished it up without a problem though, then the whole thing is weighted flat to the table, and the bottom skin-rib rivets inserted. These are blind rivets everywhere but the outboard end rib, which can be squeezed. I also used blind rivets at the most aft location in the top skins, same as on the elevators & rudder…those ribs are so narrow at the aft end that it’s nearly impossible to buck anything in there, and certainly not with any of the bars I have.

Once the skins are in place, the weights are put back in place for the trailing edge riveting, which I’m doing using the same squeezing process I’ve used on all the other control surfaces. I had to leave for work before finishing up this flap, but it’s nearly done.

Hours: 3.6 | Posted in Flaps |