Punching the list

Another warm day (but this time breezy and hazy as well). Trying to cross things off the list…

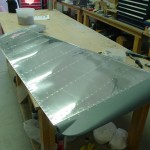

First on the agenda: loaded up the empennage and moved it to the hangar, where it will wait with the wings until final assembly.

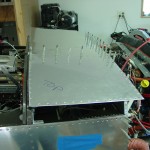

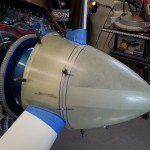

Next, set up the day’s fiberglass job. Added a couple plies to the nose flange layup from yesterday, to give it more stiffness. Closed off the inboard ends of the cooling inlet ramps with a 2-ply layup. Added flox to a couple spots and deep voids. Again today, I meant to get two rounds done, so one could cure overnight, but ran out of day.

Spent awhile fussing with canopy seals. The edge-gripper bulb seal I wanted to use on the front seems a bit too thick, as it’s interfering with the closing of the canopy — the latch requires immense force to actuate. So, that was removed for now. I added the same bulb seal to the side rails, and that also cause latch trouble, so I ended up slicing the bulb in half for about 60% of the length of the side rails. It looks ragged when open, but seals fine when closed. This is easy to replace later — I’m searching for a smaller bulb, but the 3/8″ is the smallest I’ve found so far. I may have to explore using foam strips or something. Also ran into trouble with the rear rollbar seal, again, difficult to close & latch. Will explore more seals; it seems this is a spot everyone struggles to make work.

On to the “little stuff:”

- Slipped some clear tubing over a couple fluid lines in the tunnel to prevent any possible chafing from wire bundles (clearance is fine, but vibration does things…)

- Installed the fuel selector & torqued all the fluid fittings in the center tunnel.

- Installed the fuel pump and torqued those fittings.

- Installed the metal plug in the hole that provides access to the nose leg bolt. Sealed up with a good layer of firewall sealant on both sides.

- Installed the bolts on the RH lap belt, having received my order of hardware from Spruce.

- Finished off the firewall wiring passthrus per instructions, since wiring is complete.

- Torqued the forward bearing on the aft elevator pushrod.

- Checked that all bolts on the flight controls were torqued, and torqued them where they were not.

- Swept the shop and put away tools, brake bleeding stuff, and so on.

Hours: 8.0 | Posted in Cabin & Interior, Canopy & Frame, Cowling & Baffles, Engine, Plumbing, Wing & Tail Joins | Comments Off