Wingtips again

Stole a day from work and spent it at the airport instead.

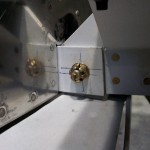

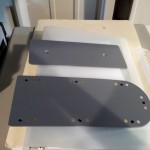

Marked and drilled the hinges to the wingtips, using the holes match-drilled yesterday. Those holes are used to secure the inboard hinge side, and another parallel row was added to secure the outboard hinge side.

Cut the flange off the wingtips in the areas that have hinge underneath. The resulting fiberglass strip (which matches the varying thickness of the tip) is then used as a spacer between the inboard hinge and the wing. Used a straight sanding block to true the edge of the wingtip. When cutting, I stayed to the inside of the molded joggle, so that the small gap left by the blade kerf is hidden as much as possible under the wing skin.

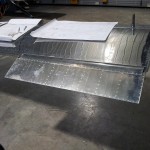

Fit the hinge halves and spacer strips to the wings, and pinned the tips in place. Checked adjustment and decided to go ahead and bite the bullet on fixing the TE alignment, so I cut the TE’s open on both tips (which were out of alignment by the same amount, around 3/16″ low). Moved them where they belonged and drilled 3 holes in the TE, then clecoed together to hold the alignment.

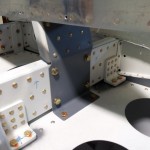

Monkeyed around with the wingtip ribs for awhile; I modified the aft ribs (which close out the part of the tip visible outboard of the aileron) to be shorter so as not to interfere with the hinges or my big foam rib. After careful adjustment and fitting to ensure the TE and aft end of the tip were well-aligned with the neutral aileron, I drilled the rib to the tip. This locks the alignment in place.

Trimmed the hinge pins down to a reasonable length; they’ll be trimmed again and bent to provide a method of securing them to the aft rib, but there was tons of excess length. Now I don’t need to worry about snagging & bending them as I walk around the plane.

All that done, and Allison having brought out my box of fiberglass supplies & epoxy, I mixed up some flox and laid a thick line inside the TE, then re-clecoed everything in its proper place. Smoothed and scraped the excess that oozed out, and left it to cure overnight. I’ll pull the clecoes and then fill the cleco holes with more epoxy.

I don’t want to disturb the tips until the epoxy cures, so I worked on other things…adjusted the inboard “ears” on the flaps, to make them sit flush against the bottom fuselage skin, and fooled around with the EFIS for awhile.

Heard Bob Collins (RV-7A in phase 1) making traffic calls in the pattern and stuck my head out in time to catch his takeoff. (This morning he has a post up about the round-robin evening flight). A nice night, so I popped the big door open a bit to get some fresh air while sweeping up the hangar.