Putting it together

Hours: 7.5 | Posted in Endgame, Plumbing, Wing & Tail JoinsFinal assembly continues. Finished off the wing bolts — all the -4′s for each wing, and the rear spar bolts. Also installed the screws along the belly skin-to-wing joints. Vacuumed the crud out of the seat pan area, and reinstalled the comm antennas. Trimmed & connected the AOA pressure lines. I need to grab the pitot union connector from home to hook that up.

Found my latest mistake, though: I was supposed to install a nutplate on the tank attach bracket before mounting the wings. Oops. The brackets in question are well-attached to the fuel tank, but I should be able to remove their mates from either side of the fuselage for access, drill and rivet the nutplates, then reinstall the fuselage brackets and we’re back in business. Less than an hour, I’d estimate. (I would have done this today, but didn’t think of it until now…in my mind, I needed to email Van’s to see if a different bolt arrangement would work here.)

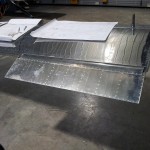

Massaged the RH fuel feed line to adjust its position in relation to the tank nipple. Removed the vent line stubs from both sides and replaced them with new, longer versions. Tightened and marked feed & vent lines on both sides. Adjusted the tension bolt on the fuel caps. Installed ring terminals on the fuel level sender wires, and connected them to the senders. The fuel system is now complete.

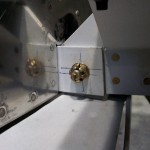

One by one, removed the four bolts holding the VS to the HS forward spar, and added a washer under the bolt head. This in response to consensus on a recent VAF thread after someone found a crack propagating from one of these slotted holes. The washer’s purpose is to provide a larger bearing area for the clamping force of the bolt. Retorqued & marked.

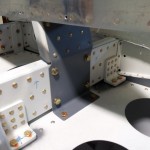

Loosely connected the aileron pushrods to the bellcranks and control column, and inserted the smaller pushrods from the rear of the wings. Pinned the ailerons in place and fooled around with pushrod positioning, stops, surface throw, etc. It’s nearly right as is, but I want to bring a round file and Dremel sanding drum and “customize” the pushrod holes a wee bit more, to make it just right. I also need to rivet on the aileron stops, which are only clecoed right now. Once that’s done, the ailerons can be installed and we can move on to flaps.