4th

June

2009

Set up the right tank for a leak test…as with the left tank, still fighting with the tape over the fuel cap, but after a couple tries, I think I got it to seal tight. The pressure held fairly consistently until the temperature started to fall as the sun went down, and there were no bubbles observed on the spray-with-soapy-water check (except for the plug in the drain fitting, which I tightened to stop the leak), so I’m optimistic about this one. Having no obvious leaks makes me feel almost as if something’s gone wrong, since reports of leaks on initial testing seem to be common…I suppose the true test will be in several years, when they see fuel for the first time. Left the tank set up on the manometer, and will check again tomorrow to see how it fared.

Hours: 1.3 | Posted in Fuel Tanks |

2nd

June

2009

Completed lots of little tasks on the wings today…

- Deburred the top skins and J-channels for the right wing; they’re ready to be dimpled, then etched & primed.

- Finished up the skin-rib rivets on the left wing top skins with Allison.

- Clecoed the left wing J-channels in place; ready to be riveted (along with the skin-spar rivets).

- Riveted the skin-rear spar rivets on the left wing. Easy enough with the squeezer and 4-inch yoke, but the 5 inboard-most rivets are a bear, due to the thickness of the reinforcing bar and doubler plates that comprise the root of the spar. Some creative combinations of squeezing and bucking were required here (eg. half-squeeze to hold the rivet in place, then wiggle the bucking bar in place and finish with the gun, since the squeezer is off center due to the spar bars).

With any luck, the left wing structure ought to be fully riveted by the weekend, and the right wing should be ready to go. I’ll need to look at the plans for the wing cart, as well, and see what I need to pick up for parts. The time is drawing near for the wings to come out of the stands! (Stands were built January 2, 2009.) I also have a plan for adding a second level of shelving to the rollaround workbench to increase its part-storage capacity, which (along with the removal of the wing jigs) will get the fuse parts organized, recovering one space in the garage for summer storm season, and allowing access to the bathroom remodel parts currently stored behind the fuselage kit…

Hours: 5.8 | Posted in Skin Panels |

2nd

June

2009

Hopefully the last session with Proseal, at least on the tanks… Encapsulated the rivet heads on all the skin-baffle rivets, checked over all the external seams and touched up anything that didn’t look 100%, then sealed on the access plate. Swiped some screws out of the fuselage kit hardware for now…will order replacements on the next order from Van’s or elsewhere — $1.50 worth of screws and $10 (or whatever) of shipping didn’t seem like the best use of funds. This tank should be ready for leak testing this weekend.

Hours: 2.1 | Posted in Fuel Tanks |

31st

May

2009

Opened the second can of Proseal, and installed the right tank rear baffle. Same process as the first, using the ziploc bag of sealant. Butter the rear of the ribs, drop blobs in the four corners, lines along the rivet holes, butter up the baffle seams, and drop it in place. Cleco every other hole, rivet on the Z-brackets, squeeze the skin-baffle rivets. Fillet the rear seam, encapsulate the baffle-rib rivets, and peel off the tape. Encapsulation of the skin-baffle rivet heads will have to wait for another day, as the Proseal was getting rather stiff by the end of the session. I mixed about 205 grams of sealant, which was enough to do everything here with some left over. (Of course, a good portion of that squeezed out and was wiped off…)

All in all, not bad progress. The confidence boost gained by the successful leak test on the left tank helped, as well. I need to pick up some replacement screws for the access cover before the next sealing session (which, with some luck, should be the last!) As before, I left the tank sitting with the baffle down, in hopes that the sealant will flow into the seam and prevent any leaks. Finally, cleaned all the Proseal off the various tools…still have a bucket of clecos to un-glob, once the stuff sets up.

Hours: 5.6 | Posted in Fuel Tanks |

31st

May

2009

Finished the remaining rivets on the inboard skin ribs with Allison.

Hours: 0.4 | Posted in Skin Panels |

30th

May

2009

Stole Allison away from her work for a couple relatively short riveting sessions. We set half of the skin-rib rivets on the left wing; with the swivel set on the rivet gun, she’s shooting like a pro. Pulled the clecoes from the ribs, now ready to fill in the other half of the rivets, and the spar lines. At least part of the rear spar should be squeezable.

Hours: 1.2 | Posted in Skin Panels |

29th

May

2009

After assembling the left tank to the spar, I prepped & primed the left wing skins and J-stiffeners. The primer goes on nicely and dries quickly in the warmer temperatures and light wind, making the priming less of a chore…but standing in the sun next to the bare aluminum skins is like a solar cooker!

Once the primer had a chance to cure, I assembled the skins to the skeleton, again checking and re-checking the plumb bobs for twist. The wing is pretty much dead on…less than 1/32″ difference from inboard to outboard end. Clecoed every other hole…ready to rivet!

Hours: 2.8 | Posted in Skin Panels |

29th

May

2009

An afternoon of progress! Began by taking the left tank out of the leak test setup and stashing those pieces for the right tank test. I primed the tank’s top & bottom inside rear skins–where it contacts the spar–as well as the outboard end where it overlaps the splice strip. I don’t know if this is really necessary or not, but since it’s in contact with other pieces, and I was setting up to prime today anyway, I figured it wouldn’t hurt anything.

After the primer had set, dropped the tank onto the spar and bolted in place, which went easily enough. Followed up by installing the tank-to-spar screws, and only messed up the heads on 8 or so…sigh. I think I need to find some better screwdriver bits. They’re not too bad, but they’re a bit screwed up in the forward direction. Throughout the process of attaching the tank, I was measuring and re-measuring the plumb lines to check for wing twist, but it stayed right on the whole time.

Some folks have trouble with the fit between the leading edge and the fuel tank, but mine is close enough that I don’t think it’s worth fretting over; it’s out by a half-skin-thickness in a couple places, but not bothersome. I think this may be caused in part by the flat nutplates riveted to the curved splice strip, pushing it out of the necessary curve profile.

Later, I went back and did a final torque of the tank-spar bolts, and marked each one with torque-seal.

Hours: 2.8 | Posted in Fuel Tanks |

28th

May

2009

I’ve spent several days of on-and-off fiddling with the leak test of the left fuel tank, but am finally ready to declare victory. It’s been holding pressure for almost 24 hours now, and passed the soapy-water test without any bubbles. The fuel cap was the fly in this ointment–I had a bear of a time getting a leak-free seal. The key, I think, is to use only as much tape as is required. I was over-zealous with the tape for the first few go-rounds, which just created more joints where the air could leak out. I tried the rubber glove trick…nope. Tried chapstick (not having any Fuel Lube/EZ Turn) on the o-ring…nope. (I have the “deluxe locking caps.”) Finally, two very carefully-placed strips of packing tape seem to have done the job.

Pressure test was conducted using a homemade U-tube manometer built of small tubing, duct taped to one of the workbench legs. The tubing is fit onto a stub of aluminum tubing and attached to the vent line fitting. The tank drain was capped with the schrader valve from Van’s leak-test kit, however, I didn’t use that as the inflater, since I don’t have a bicycle hand pump (didn’t want to blow the tank by trying to use the compressor, either). A piece of flared 3/8″ tubing was attached to the fuel suction fitting, and a short length of larger vinyl tube fit to the end. Blow into the tube until the desired pressure is observed, fold the tube over, and clamp with a small vise-grips. Perfect. (The vinyl tubing didn’t leak–it’s ID was small enough that I had to heat it in order to slip it on the aluminum tubes. Had there been leaks, I have some hose clamps that would have fit both junctions.)

Hours: 3.0 | Posted in Fuel Tanks |

17th

May

2009

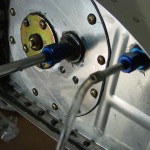

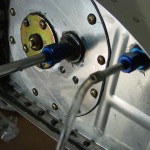

With the leftover Proseal from the left tank, I decided to install the AOA wing components, since they need sealant between the fittings inside the wing and the skin of the leading edge, in which a #60 hole is drilled for the actual port. The install is fairly straightforward, as AFS provides measurements for properly locating the upper & lower ports. They are installed at the same chord location, but offset a few inches from each other spanwise. On the 9 wing, they end up behind the cutout for the leading edge lights, but the AFS guys indicate that’s no problem. In addition to the two ports, a small hole is drilled in the bottom skin so that a plunger can be inserted to actuate the quick-drain at the bottom of the upper port (allowing any water which may have entered via the upper port to be drained from the system).

Of course, nothing is ever as easy as it seems; the port fittings install with two countersunk screws, which can fit into a #30 dimple (though they’re not actually #30 screws, it seems). Drilling them was easy (remove the brass barb from the lower port fitting, and use it as a guide to mark the hole locations). However, having already installed the leading edge to the wing, dimpling those holes was proved interesting. There is no way to get a squeezer in there, as the end rib is in the way, plus the ports are 4.75 and 7.5 inches inboard from the skin edge. I experimented with various tools, assemblies of tools, and different ideas without success. I finally decided to do what is done on the rear spar: dimple, then “ream out” the dimple. I dimpled to #40 with the pop-rivet dimplers, then used a #30 countersink in a microstop cage, going one step at a time deeper until the screws sat just flush with the skin. Having already dimpled the skin prevented the countersink from having to remove too much material.

It may not be the perfect way to install these, but they’re in, and it’s what I had available. Word to the wise: figure out these locations when you have the assembly clecoed together for the first time, and dimple them with a C-frame type tool! Either that, or buy the #30 pop-rivet dimplers that I now see are available. I don’t know if these will be needed elsewhere on the plane, but I may toss in a set with my next order of something, just to have around in case. It’s a solution in need of a problem just like the one I had tonight.

After all that, I even found time to tidy up the shop and put away the various tools that have been laying around.

Hours: 2.1 | Posted in Accessories & Mods |