Leak check passed!

Hours: 3.0 | Posted in Fuel TanksI’ve spent several days of on-and-off fiddling with the leak test of the left fuel tank, but am finally ready to declare victory. It’s been holding pressure for almost 24 hours now, and passed the soapy-water test without any bubbles. The fuel cap was the fly in this ointment–I had a bear of a time getting a leak-free seal. The key, I think, is to use only as much tape as is required. I was over-zealous with the tape for the first few go-rounds, which just created more joints where the air could leak out. I tried the rubber glove trick…nope. Tried chapstick (not having any Fuel Lube/EZ Turn) on the o-ring…nope. (I have the “deluxe locking caps.”) Finally, two very carefully-placed strips of packing tape seem to have done the job.

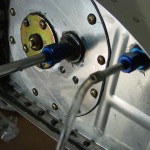

Pressure test was conducted using a homemade U-tube manometer built of small tubing, duct taped to one of the workbench legs. The tubing is fit onto a stub of aluminum tubing and attached to the vent line fitting. The tank drain was capped with the schrader valve from Van’s leak-test kit, however, I didn’t use that as the inflater, since I don’t have a bicycle hand pump (didn’t want to blow the tank by trying to use the compressor, either). A piece of flared 3/8″ tubing was attached to the fuel suction fitting, and a short length of larger vinyl tube fit to the end. Blow into the tube until the desired pressure is observed, fold the tube over, and clamp with a small vise-grips. Perfect. (The vinyl tubing didn’t leak–it’s ID was small enough that I had to heat it in order to slip it on the aluminum tubes. Had there been leaks, I have some hose clamps that would have fit both junctions.)