Left tank done

Concert season is winding its way to a close, lawn is mowed and the garden is ready for planting; finally a chance to get back into the shop for some quality Proseal time. Finished up the left tank today, with only one major moment of frustration…

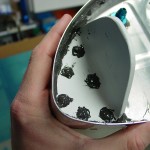

Before sealing things up for good, I gave as much of the tank as I could see an look-over with light & inspection mirror, with a special eye toward the skin-baffle joint and the four outside corners that received the “blobs” of sealant. Everything looks good, but that can mean nothing–the proof is in the leak test. Ran two beads of sealant from a syringe around the access plate opening, and clecoed it in place without trouble, then replaces clecoes with screws one-by-one in a star pattern, like lug nuts or head bolts, also twirling each screw in Proseal, and dabbing a bit in the hole, so that I ended up with a bed of sealant squeezed out around each screw head.

When the access plate was sealed on, all the screws in place, I began to go back with the torque wrench to check their tightness…that’s when it happened. The second screw I torqued snapped off. My smallest extractor was too big, so out came the other 11 screws, and a vise-grip was the tool of choice to run the broken screw fragment out the back of the nutplate (plan B would have been to drill off and replace the nutplate, but that has a greater risk of contaminating the inside of the tank with aluminum shavings). Cleaned up the sealant with acetone, and did it all over again. I used the screws that had been set aside for the second tank, as I didn’t know which of the 11 screws was the first one I torqued–I didn’t want to have another screw snap off, if I’d streched the first one. I’ll pick up some replacement screws for the second tank; maybe even the hex-head cap screws some folks like to use.

I’ve heard of people over-torquing these AN fasteners many times, which is why I bought an in-lb wrench to use…I guess 20-25 in-lb is still too close to the bottom of it’s adjustment range to be accurate. On the second try, I didn’t use the wrench, electing to use instead the ancient “gudentite” torque system. (I did use the wrench on a bolt clamped in the vise, to get a feel for the required amount of torque…I’m confident I’m acceptably tight. If these were structural fasteners, I’d try to find a decent torque screwdriver, but they didn’t have any at the stores I visited when looking for the in-lb wrench.)

With the access plate fun out of the way, I encapsulated the heads of all the rib-baffle and skin-baffle rivets. After a few days to cure, this tank will be ready for pressure test.

Hours: 2.6 | Posted in Fuel Tanks, Wings | Comments Off