Skeleton riveting

Hours: 7.5 | Posted in Spars & SkeletonStarted out with a pile of primed parts and spars. Lesson one: remove any blue tape used for masking as soon as possible…I covered the gaps of the upper and lower flanges with tape to keep metal chips from the countersinking from falling in, and ended up spending a fair bit of time removing it, and the adhesive goo it left behind. (Yes, this was the blue, easy-removal “painters” tape.) A heat gun helped more of the adhesive come off with the tape, and acetone cleaned up the rest.

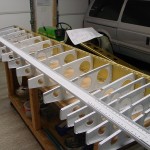

Riveted the rear spar components together to form complete spars; careful attention required here to avoid filling any holes needed for other pieces later on. A close look at the plans in the area of the outboard aileron hinges revealed a previously overlooked detail; that the outboard rib is attached to the rear spar with flush rivets, so the aileron bracket can fit over those rivets. Dimpled the outboard rib, rear spar, and spar doubler on each wing.

Clamped the left main spar to the bench and attached the ribs one at a time from the outboard end inward, which worked well. Once those were in place, I riveted the front tabs of the ribs which are beneath the fuel tanks to the countersunk holes in the spar. (There’s no specific mention of this in the instructions, but it’s clear from the plans what needs to be done here…whether this was the best time to do it will be decided later.) Clecoed the rear spar to the ribs, and riveted that on–all those rivets are squeezable, which is nice. The right wing has nicer rivets, as I changed the way I was using the rivet gun by lowering the pressure at the compressor regulator, and opening the restrictor on the gun fully. This seemed to provide a more even series of hits than a higher pressure dialed down at the restrictor. (The theory is that because the restrictor controls flow, not pressure, the first hits of the gun are at full line pressure–since the pressure has time to equalize across the restrictor orifice–with subsequent hits at a lower power due to the restricted flow.) Finished the right main spar-to-rib rivets, but still need to squeeze the rib tabs and rear spar attach.

Also getting a little frustrated by the heater…works great when it fires, but it fires very randomly, with many failed ignitions. I’ve checked input pressure and manifold pressure with a simple U-tube manometer, and both look OK. I’m wondering if the saftety check-valve gizmo installed in the line (it came with the CSST that I used to go from the valve to the inlet connection; it’s supposed to close in the event of a breakage of the flex line) is causing a problem. I might remove that from the line and see what happens, and will also double-check the spark ignitor, but it appears to function correctly.