16th

November

2009

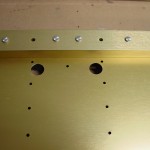

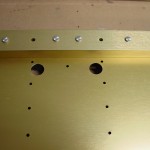

Procrastinating from other tasks, I spent the day in the shop… First order of business was to finish up the riveting of the firewall, which went smoothly. Next, I undertook again the task of the F-705 bulkhead; I clamped and drilled the lower bar and doubler bars (which make up the rear spar carrythru) to the lower bulkhead piece, along with the spacer blocks that go between them. I haven’t yet cut the tapers on the doubler bars, though.

Once those pieces were drilled, I started on more fabrication: the seat bracket holders, which are comprised of a spacer, a piece of aluminum sheet which receives a bend, and an angle. Repeat for left & right sides. First all the pieces were cut to length and deburred, then drilled to the bulkhead, and the angle (specified at 4*, but I used the “keep whacking it until it fits right” measurement…) bent into the pieces of sheet. Having no bending brake, I clamped them to the table with the bend line at the edge and a 2×4 on top, then bent them using an alternation of coaxing them by running a wooden block along the edge and applying pressure, and whacking them with a light rubber mallet. Check for straightness by sighting along the edge. Deburred the drilled holes and clecoed together.

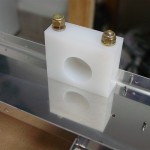

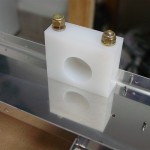

Marked and drilled the lower hole in the flap bushing blocks, then fit to the bulkhead and drilled the other hole. The UHMW plastic is interesting to work with; it machines very smoothly, and the stuff is very solid.

Screwup chronicle for the day: drilled all four left-handed seatbelt anchors as indicated in the instructions, then bolted to the bulkhead. Clamped the first right-handed anchor in place with the 3/16″ spacer and back-drilled…something not right here. Turns out I misread the plan and measured from the wrong place when drilling the left-handed anchors, which offset them all enough that the hole on the right-handed piece comes out without enough clearance to the inside of the angle to fit the bolt & washer. Arrgh. So, I need 5 new anchors–4 lefts and a right, at a bot over $ a pop plus shipping. Lesson learned: be especially careful when doing things assembly-line fashion.

Hours: 6.8 | Posted in Bulkheads |

12th

November

2009

Clecoed the painted firewall corner pieces in place, then set all the -3 rivets on the firewall.

Hours: 0.6 | Posted in Bulkheads |

9th

November

2009

Drilled out and replaced several rivets on the center section that I was unhappy with (those that hold the web stiffeners to the web of the forward piece). A couple were standing proud of flush, and needed a touch with the countersink, plus I forgot to spot-prime all six. So they’re now primed and replaced. Riveted the inner cover brackets in place as well, so the center section can be set aside for now.

Laid out and clecoed the firewall components to the firewall in preparation for riveting. Discovered that I was mistaken in my mental picture of how a couple of pieces laid in there, so two small spacer pieces which needed interior color paint didn’t get it. While I was at it, decided to scuff up and spray the power-coated steel corner pieces, as well. Will hit them again with the spray can in the morning for the second coat, and they should be ready when I get back to the project at the end of the week.

Hours: 1.4 | Posted in Bulkheads |

7th

November

2009

An unexpected warm weekend provided the perfect opportunity to prime the parts I had ready — essentially, the firewall and center section components, plus the aileron pushrods left from the wings. The air was right for priming, warm and dry, and things moved quickly, though I did have to etch & dry the parts first. After priming the parts, I let them dry for awhile, then sprayed the visible side of the firewall parts with Rustoleum Hammered from a rattle can. We picked out the Dark Bronze color the other day at Menards, and I think it looks nice. I was impressed with the pictures I saw from some other builders who used this paint, and though it may not be as durable as something like JetFlex (nor come in as many color options), I appreciate the fact that it can be easily touched up by buying another can from any hardware store. Word on the street is that it reaches its max hardness after a week or two of curing.

While I had the primer out, I poured some into the aileron pushrods to coat the insides, and pop-riveted the ends on. (Hint: don’t prime the mating surfaces of the pushrod and the end piece, rather, install them “wet,” as the thickness of two coats of primer makes an already tight fit an impossible one.) Later in the evening, I squeezed the nutplates onto the center section pieces, and riveted the web stiffeners to the forward bulkhead, as well as dug up and installed the snap bushings.

Hours: 5.5 | Posted in Bulkheads, Wings |

31st

October

2009

Started off tonight with more center section — I picked up some hardware-store Grade 8 bolts to use as temporaries in the wing spar bolt holes, two large and two small on each side. Then I set to fabricating the 1 7/16″ aluminum tube spacers that go on bolts between the bulkheads (not the wooden ones). After making four perfect spacers, I realized that only two were called for. Somehow, I’d been thinking I needed a top and bottom set, and in the process used up the second piece of tubing, which must have been intended for a later part. Will have to order a new chunk in the next Van’s order.

With that said, I now had two extra spacers…so I made sure they fit where they were supposed to, and drilled those holes in the bulkheads to size. Then I removed those two and placed them around the 1/4″ bolts at the top and bottom of each side–voila, they’ve taken the place of the wooden spacers. (I’ve read of some folks using PVC pipe chunks instead of wooden spacers, so using these extra tube pieces, which I took great care to get the correct size, should work.)

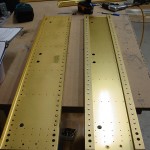

Moving beyond the center section, work began on the F-705 bulkhead, which is the structural member that the rear spar attaches to, and also provides support to hold the seats upright, and latch the canopy shut. The bottom of the bulkhead involves some large aluminum bar stock, which I cut to length, deburred, and marked as appropriate. I also cut to length the doubler bars and rough-cut the spacers that go between the two pieces.

This bulkhead appears to be the place where the instructions become quite terse. “The details are on drawing 20″ seems to indicate “use drawing 20 to figure out what you need to fabricate, bend, drill, countersink, and so on; we’re only going to mention the big important stuff here.” I’m fine reading the drawings–in fact, I enjoy working from the drawings and visualizing how the parts fit together–but I do see what others have commented on in the disappearance of hand-holding from Van’s.

Life is crazy, but shop time is cheap therapy.

Hours: 2.4 | Posted in Bulkheads |

26th

October

2009

Work sessions are becoming fewer and farther between as the pace of the academic/work year picks up. Started tonight by removing the control column from the center section bulkhead and setting it aside. Drilled, deburred, countersunk, spot-primed, and installed the nutplates on the top of the forward and aft bulkhead pieces. Fit and drilled the cover plate brackets, then deburred the edges and drilled the snap bushing holes and nutplate holes. These will be fit with the nutplates after priming. Finished up by fabricating the web stiffeners, drilling and countersinking as appropriate. There’s a pile of parts that need priming, then the center section can be riveted, at least as far as it goes for now. I also need to build the 1 7/16″ spacer blocks that are used in the assembly of the center section.

Hours: 2.6 | Posted in Bulkheads |

19th

October

2009

Cut and shaped the brackets that hold the control column to the spar, bolted them in place, then assembled the controls onto the brackets. Some finesse adjusting required here, as things don’t fit quite right out of the box. The techniques that are used in the aileron bellcranks are useful here–chucking the brass bushings in the drill press to file them to length, for instance.

Locating all the right washers and such proved interesting as well, and tells me that I really ought to get an organizer or three and put the hardware bags in compartments by type, rather than looking them up by bag number. For one, there are multiple bags containing the same part (washers or nuts, for instance). With the assumption that I will eventually perform that organizational task, I’m just using the parts as I come across them in whatever bag, unless the bag is marked for a specific use (eg. tip-up hardware or belt attach bolts).

The directions say that the control column assembly may be removed as a unit…as others before me have noted, this is impossible, since you can’t remove the attach bolts without removing the stick bases first. Getting all those washers back in there will be fun when it’s installed in the airplane…

Hours: 2.6 | Posted in Bulkheads |

18th

October

2009

Riveted the vertical pieces of the fore and aft center section bulkheads, as well as the thick spacer bars that go on the aft section. The -14 rivets called out here are not quite long enough, but they are the longest ones provided in the kit. It appears that their function is basically to hold the bars in place, much like the rivets on a nutplate; there are two large bolts that pass through each one and tie the wing spar to the center section bulkhead.

Hours: 1.4 | Posted in Bulkheads |

12th

October

2009

Continued work on the center section: laid out and drilled all the holes for snap bushings, drilled the thick bars that attach to the aft piece, drilled the vertical pieces to the lower spar pieces, deburred and spot-primed all the holes. Started work on the control column mounts by laying out the cut lines and drilling the holes that hold the mounts to the bulkhead. Filed down a weld spot inside the copilot stick base, so the stick slips all the way into the sleeve.

Also determined (by looking at some other websites, then re-reading the plans carefully again) that my second attempt at the fuel pump doubler was still not correct — all the rivets on this piece have their flush heads on the aft side, not just the ones on the nutplates (which are called out for attention in the manual). Hopefully, the third time will be the charm…

Hours: 2.8 | Posted in Bulkheads |

11th

October

2009

Finished deburring the firewall by filing all the edges smooth. Deburring the stainless steel wasn’t as bad as I was expecting; the sharp edges knocked down fairly easily with a file, and the small file set was well-suited for the scallops around the curved edges. After the edges were smooth (and safe), I dimpled all the holes in the firewall…easy.

Located all the parts for the center section (aka F-904 bulkhead); peeled off the blue plastic and marked left/right, etc. The first task here is to drill a series of holes for various things (like wiring, rudder cables, fuel lines, and so on) to pass through. I enlarged the four pre-drilled holes, and measured/marked a couple others before it was time to quit.

Hours: 1.0 | Posted in Bulkheads |