Moving aft

Hours: 6.8 | Posted in BulkheadsProcrastinating from other tasks, I spent the day in the shop… First order of business was to finish up the riveting of the firewall, which went smoothly. Next, I undertook again the task of the F-705 bulkhead; I clamped and drilled the lower bar and doubler bars (which make up the rear spar carrythru) to the lower bulkhead piece, along with the spacer blocks that go between them. I haven’t yet cut the tapers on the doubler bars, though.

Once those pieces were drilled, I started on more fabrication: the seat bracket holders, which are comprised of a spacer, a piece of aluminum sheet which receives a bend, and an angle. Repeat for left & right sides. First all the pieces were cut to length and deburred, then drilled to the bulkhead, and the angle (specified at 4*, but I used the “keep whacking it until it fits right” measurement…) bent into the pieces of sheet. Having no bending brake, I clamped them to the table with the bend line at the edge and a 2×4 on top, then bent them using an alternation of coaxing them by running a wooden block along the edge and applying pressure, and whacking them with a light rubber mallet. Check for straightness by sighting along the edge. Deburred the drilled holes and clecoed together.

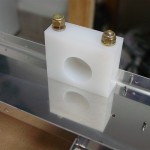

Marked and drilled the lower hole in the flap bushing blocks, then fit to the bulkhead and drilled the other hole. The UHMW plastic is interesting to work with; it machines very smoothly, and the stuff is very solid.

Screwup chronicle for the day: drilled all four left-handed seatbelt anchors as indicated in the instructions, then bolted to the bulkhead. Clamped the first right-handed anchor in place with the 3/16″ spacer and back-drilled…something not right here. Turns out I misread the plan and measured from the wrong place when drilling the left-handed anchors, which offset them all enough that the hole on the right-handed piece comes out without enough clearance to the inside of the angle to fit the bolt & washer. Arrgh. So, I need 5 new anchors–4 lefts and a right, at a bot over $ a pop plus shipping. Lesson learned: be especially careful when doing things assembly-line fashion.