25th

June

2008

Finished drilling, dimpling, and etching the trim tab components. Ended up dimpling the hinges rather than countersinking–I goofed on the elevator and dimpled the rear spar, instead of countersinking. I tested the dimples with the excess length of the hinge, and didn’t see any problems at all; no deformation of the eyes, and it nested nicely with the other dimples. Only “problem” is that it may require a longer length rivet than the plans call out, but that’s not really a problem since I have a whole case full of rivets.

Also fabricated the foam ribs, a task made easy by taping tracings of the pattern onto the foam block, rough cutting with a hacksaw, then going to the lines with the disk sander. Masked the rib locations inside the skin so everything’s ready for primer. Will try to pick up some epoxy today, so if I can get things primed tonight, tomorrow’s session should make quick work of the assembly.

Hours: 2.4 | Posted in Elevators |

24th

June

2008

Pulled all the clecoes from the trailing edges & angles…the Proseal has been drying for quite awhile, and all appeared to be straight and solid. Squeezed in rivets partway, then used a cut-off bit of the AEX wedge to shim the squeezer to the proper angle to set the rivets fully. Worked well, and they turned out nicely; there may be a teeny variation from straight here or there, but well within the allowable range, and nothing to worry about. I found that sighting the edges was made a bit frustrating by the blobs of Proseal hanging off–is that a wave in the edge, or is it just a lumpy blob of sealant?

Following dinner, I jumped on the trim tab, which went together pretty quickly. Got the hinge drilled to the tab & trimmed to length, the ends bent up, match drilled the holes, and shaped the control horn. Should be able to prep & get some primer on it tomorrow. Need to pick up some epoxy to bond in the foam riblets.

Hours: 4.0 | Posted in Elevators |

20th

June

2008

Picked up the wing kit from the ABF terminal in Owatonna today (about 60 miles away). The delivery charge saved was $75.75, plus any extra cost required for a liftgate delivery, if necessary (I didn’t inquire about the cost of that). The total freight was just over $300; a data point for others at this distance. No visible damage whatsoever to the crates, though one of the 1×1 slats was knocked off the top of the crate (visible in picture below), so it appears I got lucky.

The wing crates haul easily in a full-size pickup bed with the tailgate down. I strapped both crates down, and also strapped the spar crate forward; also elected to avoid the interstate for the trip home. At home, one of the neighbors helped unload the crates-easily accomplished by two men.

Following day: I couldn’t resist taking a peek inside…found the fuel caps, fuel senders, packing list, and other goodies. Tt appears as though there will be a great deal of paper for the recycling when the day comes to unpack…and that will be quite a day. The packing list is 6 pages long. Yikes!

Posted in Wings |

17th

June

2008

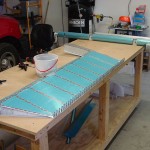

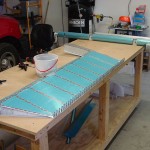

Bought a couple 8′ pieces of aluminum angle from Menards the other day, so I got the trailing edges sealed. Using the severely expired Proseal (exp. 11/07) might not have been the best idea…I had kept the tube in the fridge since receiving it, and it warmed up just fine, but the mixing head broke off the “dasher rod” when I tried to mix it. I squeezed it all out onto a piece of cardboard for manual mixing, but it took a very lumpy/ropy consistency when mixed. It was still quite sticky, so I used it by scraping off the lumps…hopefully it will work. This validates my decision to NOT order the Proseal for the fuel tanks with the wing kit. I’m not worried, since Van’s sells expired Proseal at a discount, with a note that it’ll be fine for this sort of application, but not recommended for fuel tanks.

In any event…the empennage trailing edges are clecoed to angle, awaiting the cure of the Proseal before starting to rivet. I plan to use an angled set in the squeezer to do these, and will experiment on the practice kit first.

Hours: 1.5 | Posted in Elevators, Rudder |

10th

June

2008

Spent the morning & early afternoon in the shop and got quite a bit done. After only one goof-up (I had te re-fabricate the gusset I made yesterday when it slipped while drilling and the hole was too close to the edge of the piece), I was able to finish up the riveting on the left elevator skin, mount the rod ends, and call it good.

I decided that since there was time left in the afternoon, I would start on the trailing edges, so I drilled, dimpled, and countersunk the appropriate pieces for both elevators. (The rudder was done previously.) I need to pick up a couple pieces of angle to use when pro-sealing the edges to keep them straight…I looked into using the tabletop, but it has just a bit of a wave in it. It would probably be okay (less than the 0.1″ noted in the manual), but why not try for perfect?

Hours: 4.5 | Posted in Elevators |

9th

June

2008

Began the riveting of the left elevator tonight, with the stiffeners, spar skeleton, counterbalance assembly, and the trim access plate. For some reason, that trim access hole just seems very impressive. Maybe it’s the nutplates, or maybe it’s knowing that a moving part will go in there. Also fabricated the small gusset which goes between the end rib and the rear spar; somehow I missed that earlier. Brushed on a light coat of primer so it’s ready to go for tomorrow’s session. Left to do are the tricky rivets around the inner part of the counterbalance assembly, and then closing it up.

I did take a moment yesterday to clean (acetone) and re-prime a small section on the skin where the primer was blotchy and came off very easily. When getting ready to prime, I noticed what looked like stains from our funky water, so I used some of the etch to clean them off, followed by acetone…I suspect that it didn’t get all the etch cleaned off. in any event, I wiped off the loose primer with acetone, scrubbed with some scotchbrite, cleaned again with acetone, blew dry with the compressor, and re-primed, and it’s in good shape now. Lesson learned…be more careful rinsing the parts, and be sure to get the etch cleaned off well.

Hours: 5.1 | Posted in Elevators |

8th

June

2008

Primed the left elevator components (minus trim tab) before the rain started. It’s taking forever to dry in the near-90% humidity, but I suspect an overnight spell will have it ready for some riveting tomorrow or the next day. Also pulled the right elevator out of storage and cleaned the cobwebs off. Will probably remove the blue plastic from all the empennage parts so they don’t develop corrosion, as some have reported can occur.

Hours: 1.1 | Posted in Elevators |

7th

June

2008

Short work session etching the left elevator parts for priming once dry…and with today’s humidity, that may take awhile. In other news, it appears that the primer which had separated is still usable…it’s back to normal after some extended stirring, in keeping with the instructions on the jar.

Wings should be shipped, or shipping soon. Next order of business is to read up on kit arrival/unloading. Do I need liftgate service, or is it easy enough to unload off the truck? Part of that is dependent on how much I could save by driving to the ABF terminal, which is apparently in Owatonna, about 45 miles from here. I have a full-size pickup, so that may be the best option. Still would need some ingenuity or a couple other guys to unload the crate from the truck, but that’s easier to arrange on my schedule vs. the trucking company’s schedule…

Hours: 1.0 | Posted in Elevators |

10th

April

2008

Received the letter from Van’s today, indicating the wing kit is expected to ship on the week of June 2. That’s 9 weeks from date of order. They sent me a printout of the order with a stamp on it indicating I need to sign and return it to confirm that it is correct–I’ve not heard of that procedure yet, but I’ll take it as an opportunity to amend the order and add a few things to save on shipping/handling.

Posted in Wings |

8th

April

2008

I’ve upgraded WordPress to version 2.5 tonight, and as a result, the old theme (built for a 2.0.x version) no longer works, along with some special plugins that were running, like category order and the hour totals. So, I will be working to bring those features back online in the near future. Hopefully the WordPress structure will remain the same for the future; apparently, certain things were redone in 2.3 and 2.5. If you find something really broke, please let me know! Thanks…

Posted in General |