Baffles ‘n’ more…

Hours: 6.5 | Posted in Cowling & BafflesOr, more accurately, ‘n’ more baffles… I did do one non-baffle thing today, which was to mount the capacitor for the SD-8 backup alternator next to the relay, now that I have the correct size adel clamp. The only cabin-side part of that system which can’t be pre-mounted is the regulator, since it comes as a package with the alternator. There is a dimensional drawing for it, so I could install the nutplates and hope the drawing is accurate… (Trying to be cheap and not buy it until a future upgrade date.)

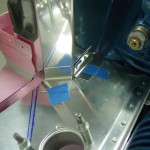

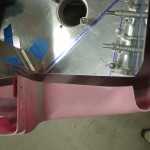

Then, back to baffles. It doesn’t look much different after a day’s work, but the inlet ramps have been bent to fit, the forward corners formed, and the conical-bend filler pieces fabricated and drilled. Trimmed the front inside corners for clearance to the flywheel and alternator belt. The ramps and stiffeners have been riveted, and holes made for the LH cabin heat take-off, and the alternator blast tube. Locations marked for the Pmag blast tubes, which will be drilled when the rear baffles come off again. The inlet ramps were trimmed to fit the cowl, with a 1/2″ gap between cowl and metal, which will be bridged by the airseal fabric.

With the inlet ramps in good shape, attention turned to the vertical pieces behind the flywheel, which took more iterative fitting to get the angles right. Made and drilled the attach clips for the right side, and cut the stock for the left before calling it a night. Need to look at my saved baffle reference links to see how the vertical piece is trimmed, as it’s not clear in the directions or included photos whether it’s trimmed back to the length of the ramps (which would make sense from a vibration standpoint) or left longer.