18th

April

2009

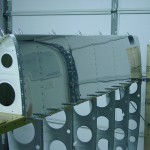

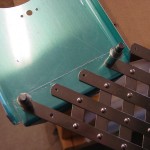

Finished dimpling the wing skeletons, and enlarged the rear spar dimples with the deburring bit as described in the manual. Checked the left wing in its fixture, re-stringing the line along the spar rivet row, and hanging the plumb lines at inboard & outboard ends. Leveled, measured and adjusted until the twist was zero, then dropped the LE assembly on top and clecoed in place.

Riveted the assembly to the spar, and managed to use all solid rivets. Going in, I was convinced that I would end up using blind rivets on many of the ribs (as many 7 builders do, with Vans’ approval), but the 9 wing design must allow more space, as I didn’t have any trouble. I did need all three of my universal-head rivet sets (straight, offset, and double-offset) in various places, and the third rib from the inboard end is a two-person job due to the reach. (Thanks to father-in-law Bob for help driving those rivets!) None needed to be drilled out, and the rows of skin-to-spar rivets went quickly with the squeezer. Left leading edge is installed!

Next will be the right LE to spar, then deburr/dimple/prime the wing skins. Still need to get a flaring tool so I can flare the ends of the tank vent lines in order to seal up the tanks.

Hours: 4.3 | Posted in Skin Panels, Spars & Skeleton |

17th

April

2009

Finished the riveting of the leading edges; worked the right assembly in the cradle, then stood both L & R on end to reach in and drive the last 3 rivets at the nose of each rib. Both came out nicely.

Primed the skin countersinks on the spar flanges, as well as dressed out & primed several bucking dings on the webs. Started dimpling the wing skeletons…lots of holes! Got a little more than halfway through.

Hours: 3.3 | Posted in Skin Panels, Spars & Skeleton |

15th

April

2009

About 3/5 of the way through riveting the leading edge assemblies. Completed the bottoms of both left and right, and the top of the right excepting the forward-most three rivets on each rib. Those are at an angle where the tabletop interferes with the rivet gun, so I’m going to finish both sides through that point; then either stand the assemblies on end to rivet those final three (the same way I did the fuel tanks), or tilt the cradle blocks so they’re accessible.

Also drilled out the tie-down ring holes in alignment with the tie-down bars bolted to the spar. Test-fit the left LE to check fit again; no problems noted.

Hours: 2.4 | Posted in Skin Panels |

11th

April

2009

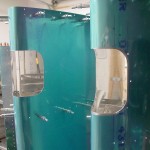

Clecoed the primed LE components together and test fit on the wing skeletons (again, to be sure they went back together correctly, remembering the trouble I had fitting the left LE the first time). No problems with the fit, so they’re ready to be riveted. Need to touch up some bucking dings on the spar before they can be riveted on for good.

Also riveted the LE light brackets together and fit the reflectors in place. These won’t go into place until the LE assemblies are riveted onto the spar, to save them from vibration. I’ll fit the lenses once the LE’s are riveted together, but probably off the spar for easier access.

Hours: 1.9 | Posted in Accessories & Mods, Skin Panels |

10th

April

2009

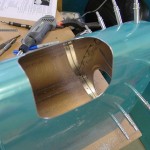

Skeleton deburring complete, and nice weather outside, I prepped & primed the leading edge skins, ribs, splice strips, and landing light components. Ready to rivet!

Hours: 4.9 | Posted in Skin Panels |

6th

April

2009

Finished deburring the left wing, and got most of the way through the remaining holes on the right wing. Should be done soon, then dimpling the skeleton can begin.

Hours: 2.0 | Posted in Spars & Skeleton |

4th

April

2009

Tech Counselor Mike Hilger paid a second visit to the project today to look over wing construction and fuel tank internals, before closing up with the back baffles. Also spent time talking about options & accessories like pitot, AOA, autopilots, and engine/avionics choices. Mike works at SteinAir and built an RV-6, so is a great and knowledgeable resource. I expect we’ll be talking more as the project continues and bigger decisions need to be made.

The last TC visit was nearly 2 years ago. Unfortunately, as slow as progress has been, things will likely slow down even more for the next couple months, as my only real building time occurs on weekends due to work during the daytime, and evening commitments at least 3 of 5 weeknights on average–and I’ve just looked over the schedule through the end of May, and there are many weekends where commitments to one, two, or all three jobs wipe out both Saturday and Sunday…coupled with extra weeknight schedules many weeks. After clearing the Memorial Day hurdle, though, I switch to a half-time summer schedule at work (two of three jobs are closely tied to the academic year) until late August. So, I hope to be able to get some solid work in during the summer. I know there are travel and remodeling plans yet to be completed, though, so we’ll see what actually transpires. Life moves quickly in this house…

Hours: 1.0 | Posted in Wings |

30th

March

2009

Wing skeleton 5/8 deburred…got the outside edges of all ribs & spars, and inside edges of bottom left wing before the batteries ran out in the deburring driver.

Hours: 1.7 | Posted in Spars & Skeleton |

29th

March

2009

Today’s task: prep leading edges for primer. Disassembled both LE’s, deburred, scuffed rivet lines, and dimpled. Drilled the splice strip for platenuts, and also finished deburring the landing light internal pieces; all the LE components are ready to be etched & primed.

In between deburring tasks, I also bolted & torqued the tiedown brackets to the spars. Bellcrack brackets are hung loosely with their bolts, awaiting installation of the bellcranks.

Received the missing F-902-L this week, along with a replacement for the gouged up piece of bar stock.

Hours: 6.6 | Posted in Skin Panels |

22nd

March

2009

Hours: 3.2 | Posted in Accessories & Mods |