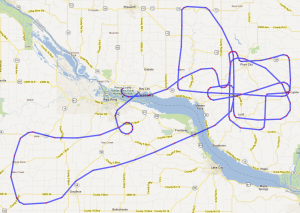

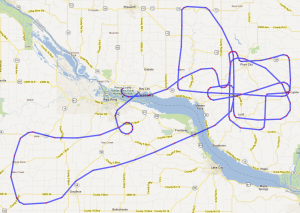

Began the day with some excitement; nearby -9A (and now -10) builder Mike Behnke was gracious enough to bring his plane down to Red Wing this morning so I could have my first RV flight — a great one! The day was warm, calm, and relatively clear, and Mike’s plane looks and flies great. My only experience being in 150/152/172 types, the stick-and-pushrod controls were a new thing, and a joy to fly; no slop in the control system, and just a bit of pressure required for control. We did some turns, stalls, a bit of sightseeing, and Mike demonstrated an autopilot-coupled GPS approach. Also got to see the AFS screens in flight, as his panel is practically identical to mine (both equipment and layout). We also chatted about fiberglass, transition training, inspections, first flights, and so on. Many thanks to Mike for the opportunity! It’s another inspiration to work through the endgame of my project.

On my way out of the airport, I stopped by the hangar and pulled the fuel caps from the wings (and taped over the filler holes), as I’m considering sending them in to be engraved with the required markings, rather than using a sticker.

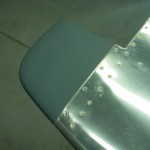

Into the shop after lunch, I spent several hours sanding the micro filler on the canopy fairing. It turned out pretty well, and I think I’m going to try and move ahead with it. To that end, I squeegeed on some straight epoxy to seal the micro and fill pinholes. I’ll add another layer or two, then sand and see where it sits.

I used the excess epoxy to seal the inside of the emp fairing. I’m hoping to get the rest of the emp tips ready to spray this week, then spray a whole batch of glass one night. Once the tips are done, the emp parts will move to the hangar.

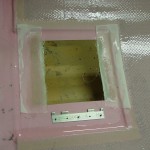

Drilled the dataplate to the fuselage — I’ll send this in for engraving with the fuel caps. Also located some 3/32 pop rivets to attach it. Since I don’t know when the inspection will be, I’m just going to put 2012 in the date box; this field isn’t even required.

Then I took a look at the top hose from oil cooler to engine; I think the bend radius on this hose is too tight, and I’ll need to order a longer hose, change the fitting on the engine, and reclock the fitting on the oil cooler, to allow a more sweeping bend in the hose. It’ll be more in the way of filter changes, but don’t want to take any chances with an oil hose collapsing.

Added a silicone boot to the oil temp sensor wire; more for vibration support of the wire than for short-circuit protection.

Stuck a label on the brake reservoir, indicating what the thing is, and the spec of the fluid it’s filled with.

Traced the spinner diameter and used some geometry to trisect it, in preparation for making the prop cutouts. Still need to figure how I’ll determine the shape of the cut, not owning one of those curve-finder pin apparatus.