18th

August

2009

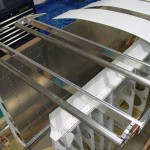

Built the flat table for aileron & flap assembly tonight…that sucker must weigh upwards of 100 pounds. The top and bottom are half-sheets of 3/4″ MDF, and the structure is most of four 2×4′s, put together with plenty of screws. It checks out flat with a 4′ straightedge, so I imagine it will serve the purpose. Also reading up on the trials and tribulations of building the control surfaces on others’ build logs.

Hours: 1.5 | Posted in Ailerons |

17th

August

2009

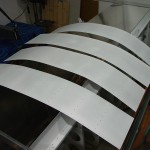

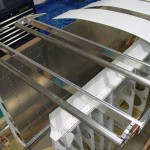

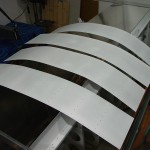

Back-riveted the stiffeners to the aileron skins, then proceeded with the assembly of the left aileron. Clecoed the bottom skin in place, drilled the ribs, deburred and dimpled. Then installed the bottom skin with the two “keeper rivets”, and clecoed the top & nose skins in place as described. The nose skin puts a great deal of force on the aileron, and the trailing edge goes really wavy, but I’ve read this is normal. Tomorrow’s task will be building the flat table for the driling & riveting of these guys, and I need to get some weights of some sort–sandbags or lead shot, I’m thinking–to hold the aileron flat to the table.

Hours: 2.0 | Posted in Ailerons |

16th

August

2009

Allison helped out tonight, dimpling the aileron skins & stiffeners while I etched for primer. After everything was dry, I went ahead and shot the primer–in a race with the setting sun–so the stiffeners are ready to back-rivet to the skins.

Hours: 3.1 | Posted in Ailerons |

15th

August

2009

Back home after two-and-a-half weeks away on “vacation.” Almost three weeks since I did any work on the plane, but I’m ready to dive into the ailerons. To that end, I started out with the tedious work — cutting, shaping, and deburring the 28 aileron stiffeners using snips, disc sander, and scotchbrite wheels.

Next, clecoed the aileron spars together with the nose ribs, then marked and drilled the counterbalance pipes (after deburring the ends to remove the very sharp stainless steel burrs). I cut a V into a scrap of 2×4 to make a holding fixture for drilling the pipe — slowest speed on the drill press, light pressure, and Boelube made easy work of the holes.

Put in the temporary rivets to attach the counterbalance to the nose ribs, and clecoed the ribs back onto the spar, then clecoed the end ribs in place. I goofed when I was match-drilling the reinforcement plates, and drilled out a couple wrong holes, which were the two holes intended for -3 rivets on the left outboard rib. I can’t see any reason why simply upgrading to -4 rivets won’t work there, or even oops rivets. Luckily, I caught myself before I had drilled all four sets…just one set is big.

Identified the various top & bottom skins and marked the for left/right, top/bottom, inside/outside, then drilled the stiffeners to all four skins. Finally, more tedious work — deburring the holes in all four skins and 28 stiffeners. Finished up by edge-finishing the four skins, and scuffing the lines where dimples are to go. The stiffeners & skins are ready for dimpling, prep, and priming.

Hours: 4.9 | Posted in Ailerons |