Beginning flaps

Hours: 5.4 | Posted in FlapsAfter lunch, work begins on the flaps. Pulled lots of blue plastic, then assembled and drilled all the nose rib/hinge assemblies. Them drilled those assemblies to the spars. Fabricated (hacksaw–oh joy!) the heavy inboard reinforcing angles and the spacer plates that go behind them–all turned out well, so they were clamped and drilled in place.

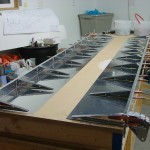

Next, the bottom skins were set up on the table and the spar assemblies attached, then the skins drilled to the table. A woodworking project ensued–drilling 54 5/8″ holes in the flat table…followed by a thorough shop-vac session. Finally, the main ribs were clecoed to the spars, ready for match-drilling in the next work session.