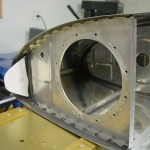

Fuel tank riveting

Hours: 5.3 | Posted in Fuel TanksFinished up the riveting of the fuel tank ribs with the bottom of the right tank. Went well; only had to drill out 2 rivets. Started installing the tank attach brackets at the inboard ends, which use long (-8) AD4 rivets. My straight 1/8″ universal-head rivet set is short, so there were two rivets on each bracket where the gun couldn’t get into position because the head hit the bracket. I tried using the double-offset set, and had no luck at all. Drilled out the same rivet twice, and another once, before giving up on those for now. Because they’re so deep into the tank, it’s hard to manage keeping the longer double-offset set straight, and the bucking bar straight, at the same time. It really requires two hands on the gun side…which leaves no hands for bucking. I do also have a single-offset set, which is definitely a two-hander. I’ve run into a bit of a human resource problem here, I think–and I fear the same problem will occur when it’s time to rivet skins on the wing. The easy solution here would be to get a longer straight-shank set to clear the bracket. Not sure what I’ll do about wing skin riveting.

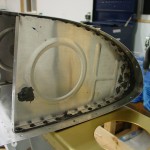

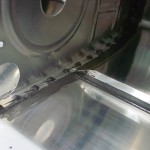

Filled a 20cc syringe with a fresh batch of Proseal (mixing weight of 35 grams yielded about 15cc of usable Proseal…it’s impossible to scrape it all off the waxed paper!) and encapsulated the shop heads of the right tank rivets. I have about 5cc leftover, so that went into the freezer. The syringe method will be handy for the small sealing jobs, I think–fittings, access panels, etc. Hopefully I can do the shop heads on the other tank tomorrow after work, and then try to get a Tech Counselor out to put another eyeball on the tanks (and other wing stuff I have done) before putting the baffles on.