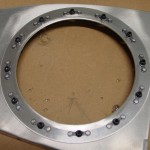

Tank end ribs & access plates

Hours: 2.4 | Posted in Fuel TanksCut the access holes in the fuel tank end ribs using the Dremel tool with a circle-cutting guide. The centering pin on the device fit perfectly into a #30 hole, so I marked the center of the circle to be cut and went to town. Cleaned up and smoothed the edges of the holes with a curved file, then used the 2″ scotchbrite wheel in the drill press to finish it off. Located and drilled the cover plate, then the reinforcement ring. Drilled for the nutplates holes, dimpled, countersunk, and deburred everything. The left side is riveted together with the nutplates, and the right is clecoed, waiting for rivets. A simple little fabrication exercise for the evening. These assemblies go together quickly when you don’t have to worry about prep & priming! (The innards of the fuel tanks remain unprimed, to avoid any reactions between the coatings and the fuel.)