Fuel tank fabrication

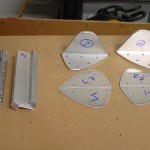

Hours: 2.8 | Posted in Fuel TanksLots of hacksaw, sander, and scotchbrite wheel work… Fabricated the inboard tank attach brackets; match-drilled them to the tanks. Fabricated and drilled the inboard and outboard reinforcement plates–used 5 rivet locations per plate. Drilled and countersunk the rivet holes on the spars that hold the inboard tank attach platenuts. Deburred all holes and fabricated pieces, plus the Z-brackets for both tanks.

My goal for this week is to be better about doing some short evening sessions; even though I’m booked with other commitments for a minimum of two nights each week, I think that would help create a feeling of progress, which in itself is a motivator. Last week was so cold (-20 lows, -5 to +5 highs for several days running) that I was reluctant to heat the shop for short sessions, plus the rest of life was busy. There’s a half page of fiddly stuff now to get the tanks ready to seal: fuel caps, tank drains, dimpling, platenuts and the like (plus priming some of the external small pieces), which ought to make fine fodder for short sessions. Here’s to progress!