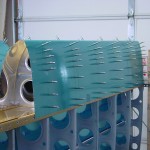

Leading edge work

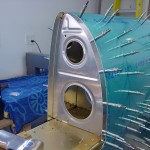

Hours: 3.5 | Posted in Skin PanelsWrapped up the leading edges in an afternoon session. Thanks to all who offered comments & suggestions on the LE fit problem; I was able to resolve it with another reassembly of the components; this time using some 24″ bar clamps to help massage the ribs into the proper place. I didn’t get any decent pictures of this procedure, but the idea came from a photo on Bret’s -9A build log (scroll down to 8/19/06; center photo). It’s easy to catch a couple clecoes in the nose area of a rib, then use a block of wood and clamps to help work it down into the skin as far as it needs to go so that clecoes will drop into the holes. The awl alignment tool is helpful also, to wiggle and coax things into place.

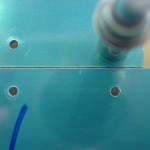

Dropped the re-assembled left LE onto the wing, and (to my relief) it fit correctly. Proceeded to match-drill all the LE skin-to-spar and -rib holes; lots of cleco-moving, as I had the left LE clecoed in nearly every hole. I did have to steal clecoes from the main skins, until I remembered a toolbox with a couple hundred extra clecoes inside…great! That gave me enough clecoes that I didn’t have to steal more for the fuel tanks.

The inboard ribs and splice strips went in with relative ease, and got those drilled in place, too.