Sand, slather, repeat

Hours: 7.0 | Posted in Cowling & BafflesThe “before airport” items on the punch list now fit onto a single printed page, so we must be getting closer, right?

I’m pushing to get the cowling to a point where I can start doing finishing work on it, rather than shaping work. I think when we get to the point of spraying the cowl, it will be a major milestone, and the light at the end will feel much brighter.

Spent several hours sanding the cowling today — smoothing edges of the cooling ramp layups, truing edges, aligning things, sanding down filler, and initial shaping of the micro blobs on the outboard nose sides, to make the top & bottom even.

Added another inch to the gear leg slot, which should provide just enough clearance from the prop to get the thing on & off without dinging either it or the prop (after protecting the prop blades with something).

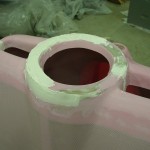

When all the sanding was done, took the halves outside and sprayed them down with the hose to remove all the dust, then dried them inside. Applied another batch of micro to the nose ring, filling the spots where the gap was wider than desired. This will be sanded back to provide a consistent even gap all around, and will probably take another layer or two of micro to finish off.

Drilled the gap filler pieces for nutplates, and countersunk those 3 holes in the spinner. Primed and riveted the spinner bulkheads, gap fillers, and gap filler flanges. At this point, the spinner is ready for fiberglass finishing.

Installed the radios into the avionics stack. All that remains to reinstall is the EFIS, which I’ve left out for now while I continue to ponder canopy seals.

Pulled the dessicant plugs from the engine to bake, as they were beginning to turn color.