Slow day

Hours: 7.1 | Posted in Electrical, EngineSpent a good portion of time in the shop today, but didn’t accomplish a great deal, it seems. I started the day with a list of what seemed like easy quick tasks, but in reality, I only checked off one thing.

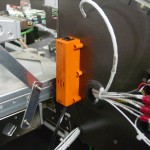

The main order of business for the day was finishing the EGT/CHT wiring FWF. Having installed or test-fit essentially everything in the area, I finished running the wire harness and sorted out which wire was which. After creating service loops and trimming to length, the wires needed to be terminated, using the recommended method (crimp, flux, solder, heatshrink) from AFS. I put heatshrink on each terminal, as they’re uninsulated; once the terminals were joined together, heatshrink went over that, then a larger piece of heatshrink to bundle the pair of wires for each probe together. It should be secure and well-protected, yet still easy enough to cut away when a probe needs to be replaced. Once everything was hooked up, I used a heat gun to check that the proper probe is wired to the proper location — the EGT’s are, but I wasn’t able to get the CHT’s to show on the display; not sure what’s going on there, although the EGT’s disappear below a certain point as well (100*, I think), so the CHT’s probably have similar logic and I just wasn’t able to heat them far enough given the larger thermal mass of the cylinders.

Other more minor tasks accomplished:

- Fabricated, fit, and painted an angle brace to go between the panel and the subpanel, to eliminate a slight flex in the left side of the panel. The brace ties into the EFIS 2 tray with a countersunk screw, and is fixed to the subpanel with a riveted clip. Will install this tomorrow once the paint is dry.

- Installed the ELT remote to the panel, and attached the audio alert box to the subpanel. The audio alert can be serviced without removal, since the cover unscrews from the base, but the remote will need to be removed again for installation of the battery. There are actually three batteries in the ELT system — one in the ELT itself, one in the remote, and another in the audio alert box. All except the ELT have to be procured by the builder. I haven’t looked yet to see if they’re all good for 5 years like the ELT battery, or if more frequent replacement is required.

- Since EFIS 1 was removed for access to fit the panel brace, I took the opportunity to enlarge the wiring hole behind it. My initial hole was large enough for the requisite wires, but the bigger, oblong hole will remove the tight bend that a few of the wires had to take, and give more space for the pitot/static/AOA tubing. Speaking of which, I found that I never ordered the fittings for the pitot/static connections to the EFIS.

- Ran switched/dimmed power and ground to a plug at the subpanel, where the panel flood lights will connect. These lights are mounted to the underside of the glareshield, which is part of the canopy, hence the need for a disconnect to allow canopy removal.