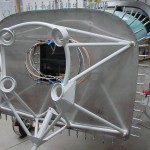

Engine mount

Hours: 2.3 | Posted in EngineBack home from the turkey trip — received an email from Aero Sport Power on Thanksgiving that my engine is nearly ready to ship. So, pending the necessary large check, I could have an engine by Christmas. I have zero done (or even parts for) the FWF stuff, so much to be ordered there. (Wonder if I can trade in some Christmas trinkets…)

Today, I read up on drilling the engine mount and did the deed. This wasn’t a big deal at all: I supported the mount with a cargo strap hooked to the center spar, and moved it around until I found the best alignment with the four corner holes. Drilled two to 1/4″ and used some fuel line scraps to make bushings for the AN6 mount holes, then pinned those in place with some long AN4 bolts and drilled the other two holes. I used some long clamps to hold the mount in place while drilling for accuracy, and drilled through a couple more pieces of fuel line. Once the 1/4″ holes were done, I removed each bolt sequentially and enlarged the hole for the AN6 bolt. After the large bolt was inserted, I moved to the next hole. Once the four corner holes were drilled and bolted, the lower inboard holes were drilled, first to 1/4″ then 3/8″. I have the common gap between the mount and the firewall at the lower inboard holes; there are some spacers with 3/8″ holes left over from the fluid fitting bags, which look as though they might work ideally as spacers there.

Once the mount was bolted on, I inserted the nose gear leg and reamed that bolt hole. I did have to scrape off a bit of extra powdercoat from the lower ring of the leg to allow it to insert completely, and polished off the light rust that had formed. Coated the exposed steel with grease for protection.

Finally, pulled the engine mount and gear leg and set it aside again. There’s plenty of holes that need to be made in the firewall before it goes on for good…and more holes to be made after. This is a chicken-and-egg part of the build, where you don’t really want to mount the engine until all (or at least most) of the FW penetrations are made and pieces mounted, but you don’t know for sure where those holes should be until the engine is mounted.