Put on a shine

Attended the quarterly gathering of the MN RV Builder’s Group this morning; saw the new -9 under construction by a repeat builder, including a nice panel being built with triple-screen G3X and GTN650. After scoping out the plane and downing some danishes, I was able to corner Tom Berge, who does nosewheel transition training locally. Picked up the info I needed to plan for transition training, and Tom also said he would be willing to conduct the first flight. He recommended I get in touch to start transition training when I’m about a month from first flight, and after getting current again.

With that sorted out, back home and time to finish the plane… First thing, as usual, was to sand down the layers which were applied yesterday. With that, I was able to finish shaping the nose, straighten up the oil door cutout, smooth the side hinge lines, and get the top skin/canopy “air scoop” fixes to the right shape.

The entire plane–and builder–being now covered in fiberglass dust, and given the lovely weather outside, I decided to roll the fuselage into the driveway and wash it. That went well, and I quickly found out where the leaks were. As I was rinsing it off, a local couple we know who had been out on their bikes rode up to check it out; Ben is a retired airline pilot and interested in the project, so we looked & chatted about that, as well as the various animals that have taken over the yard.

After drying (microfiber is amazing) and wiping up after the leaks, it was back into the shop for more work. Displaced the canopy for access and filed the aft edge of the canopy joint micro back to where it ought to be, then filled all the gaps between the skin and the weatherstrip seal with Proseal. Once set, I’ll trim any goobers and it should provide a much higher level of water/dust ingress protection. During this process, neighbor Jeff stopped by to check on the progress, having seen the plane in the driveway earlier, so chatted for awhile about various things.

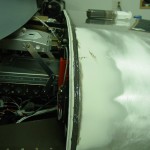

Final task for the evening was to spread a coat of epoxy on the interior surface of both cowls. This will be left as-is, to provide a solid shell which will protect the fiberglass against oil and other fluids and ease cleanup of drips. The interior of the cowls will be painted white to lighten up the engine compartment for preflight inspection, and make any leaks easier to spot. Also added some micro to fill divots in the canopy joint filler.

Milestone: rolled over 1700 hours on the project today.

Hours: 8.0 | Posted in Canopy & Frame, Cowling & Baffles, Finishing | Comments Off