Skeletons and ribs…oh my!

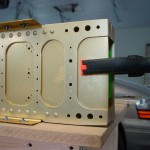

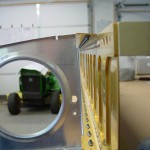

Drew up a proposed list of required wires in the wings, and went on drilling all the ribs for wiring conduit and enlarged tooling holes, after looking at other builders’ sites. Wrapped up all the ribs, and proceeded to cleco the skeleton together; hey, these are starting to look like wings!

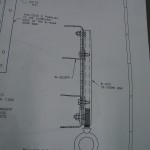

Left Wing Proposed Wiring:

- Equip List: pitot, AOA, landing light (Duckworks)

- 7/16″ Hole 1 (pitot hole; to pitot bay only): Pitot

- 7/16″ Hole 2 (to wingtip; enlarged tooling hole): Strobe pwr

- 3/4″ Conduit (root to tip): Landing Light pwr, Nav light pwr, AOA upper/lower pressure, pull string

Right Wing Proposed Wiring:

- Equip List: AP roll servo, wingtip nav antenna, taxi light (Duckworks), OAT probe

- 7/16″ Hole 1 (pitot hole; to pitot bay only): -open-

- 7/16″ Hole 2 (to wingtip; enlarged tooling hole): Strobe pwr

- 3/4″ Conduit (root to tip): Taxi light pwr, Nav light pwr, AP control, Nav ant coax, OAT, pull string

Not sure if the OAT should go in the left or right wing…probably doesn’t matter, so will depend on balancing weight and/or length of wires to EFIS.

Drilled the rib-to-spar holes, both front and rear, and took it all apart again for primer prep. Primer prep is my least favorite part of building so far…the priming isn’t bad, but the the seemingly endless etching, scrubbing, and rinsing I could do without. The time savings to go with an unprimed plane probably aren’t significant enough in the grand scheme to be worth not priming, though. Deburred all the left-wing ribs, then prepped all the rear spar components, and 7 left-wing ribs.

I’ll split up the primer prep by doing all the left wing ribs, then go back and deburr the right wing ribs before etching. I still need to come up with a scheme for an indoor priming “booth” of some sort; someone on VAF mentioned using a cheap screen gazebo, but I don’t know if a) it’s worth the cash, or b) if I’d be able to find one this time of year! I might just get some heavy plastic and drape it from the garage door tracks somehow.

Hours: 5.8 | Posted in Spars & Skeleton | Comments Off